New micro-credentials recognise 21st-century skills gained through youth arts programs

Young people who participate in arts programs develop highly sought-after workplace skills – and now they have a way to prove it.

Zapping stem cells could boost growth of new tissues and organs

Scientists in Melbourne have discovered how tiny electrical pulses can steer stem cells as they grow, opening the door to new improved ways of creating new tissues, organs, nerves and bones.

Cairns Airport mangrove study sets new standard for Indigenous-led research on country

A new study highlights how Indigenous leadership, science and business can unite to protect coastal ecosystems while building long-term environmental and cultural knowledge.

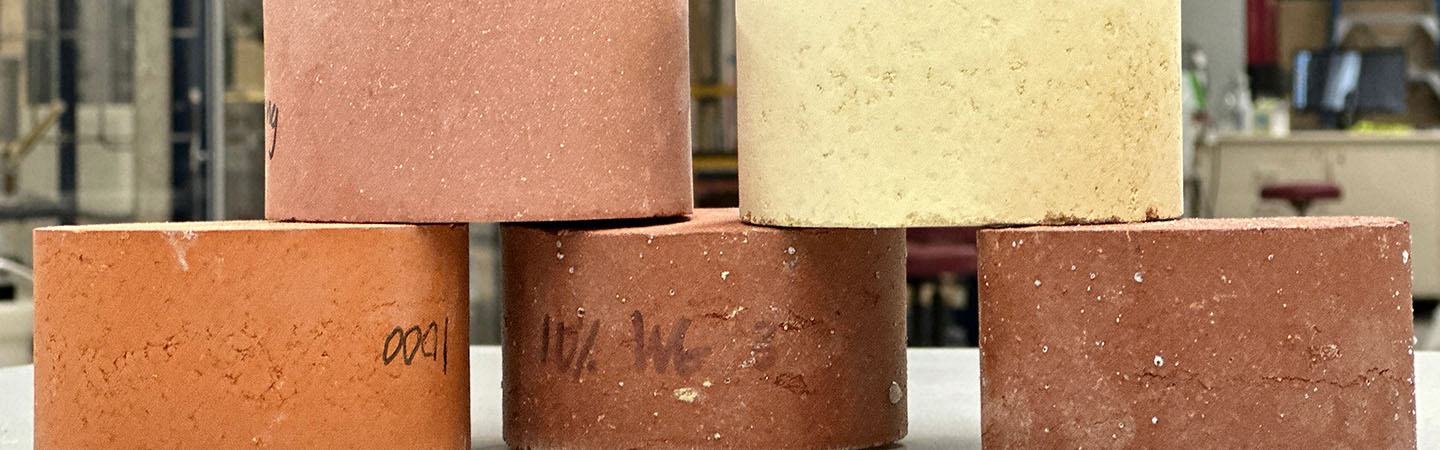

Coffee waste helps make lower carbon concrete

RMIT researchers are advancing new ways to cut the carbon footprint of infrastructure by turning everyday organic waste into useful construction materials.