Managing a supply chain can be a complex task. For that reason, understanding the basic supply chain process is important.

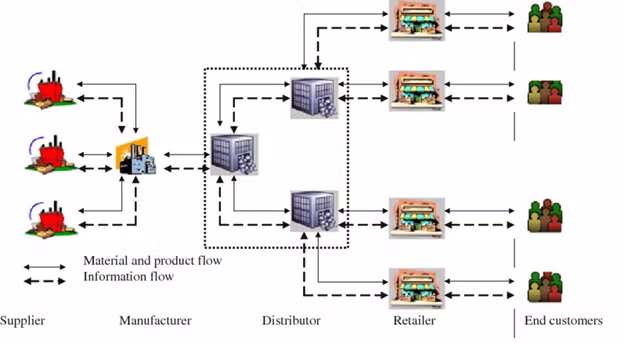

In simple terms, the supply chain process comprises the steps that are involved in creating a product or service and getting that product or service to the customer. In a supply chain, these steps can involve acquiring and collating raw materials, manufacturing and finishing a product, and selling and distributing the product to an end user. Typically, the process involves many agents, including suppliers, manufacturers, logistics professionals, warehouses, distribution centres, retailers and online stores.

A popular process model used to describe the supply chain process is the supply chain operations reference (SCOR) model. SCOR describes the various elements required to produce a product and deliver it to the customer. It includes the following elements:

- Source: Sourcing refers to the process by which goods and services are obtained to meet market demand. This includes purchasing, receiving and other supply-side activities.

- Make: Making refers to the process by which goods are produced. Finished products are created in this step so that they’re market ready.

- Deliver: Delivery refers to any step by which finished goods are delivered to customers. Steps here include transportation and distribution.

- Return: After the goods are in the hands of the customer, the process isn’t finished. The return process refers to any customer support required after delivery.

Reliable suppliers are critical throughout the SCOR process (and indeed, throughout supply chain management) as they’re responsible for sourcing, making and often delivering the product.

Another important model used to describe various parts of the supply chain is the flow of costs. The flow of costs refers to the path in which costs move through a business when the business is producing something. Typically, costs are split into the cost of raw materials and inputs, the cost of manufacturing, the cost of storage, and the cost of selling goods. Dividing costs in this way helps businesses understand where and how to optimise their supply chain processes.