Indigenous plant could have handy health benefits

New research suggests an Australian desert plant could help food manufacturers improve protein quality and reduce reliance on added salt in staple foods.

Aussie bushfire prevention tech goes global

A powerline fault detection system invented at RMIT is being rolled out globally thanks to AUD $50 million in new funding.

Study reveals value of roadkill for scientific research

Hundreds of millions of animals are killed on our roads each year. Now, scientists have revealed how these deaths could play an unexpected role advancing wildlife science and conservation.

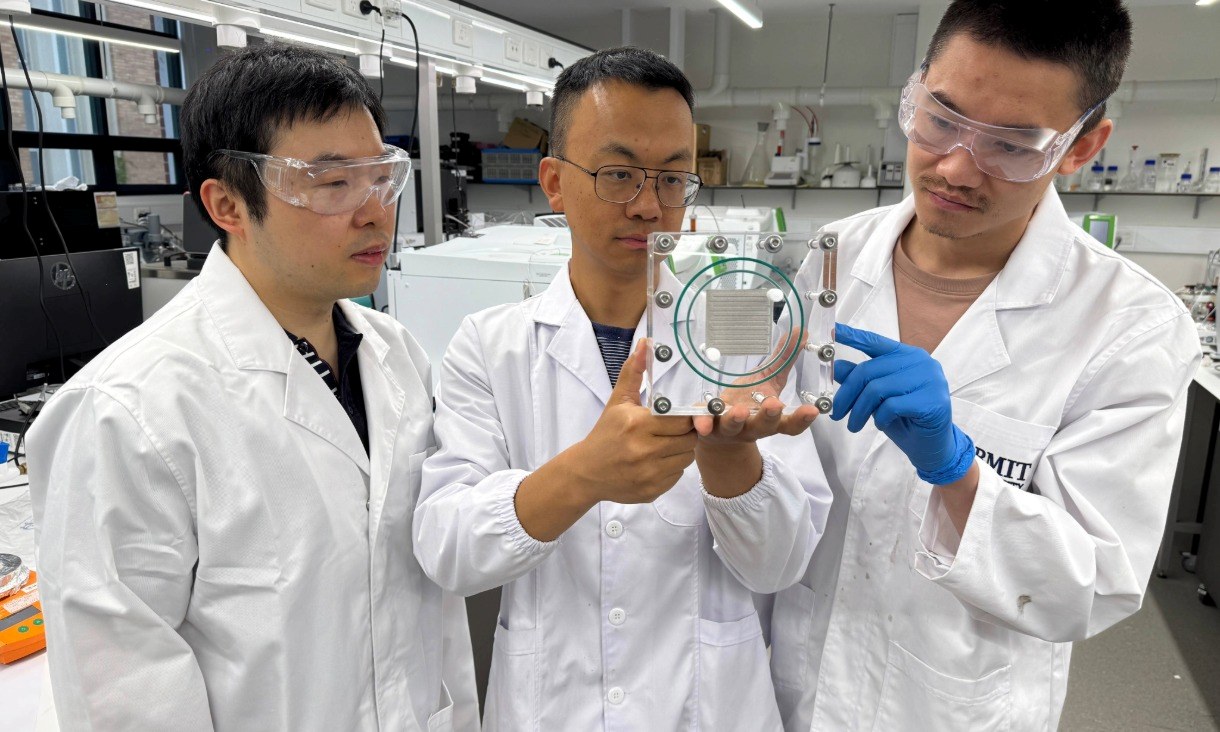

New carbon-conversion technology could turn emissions into jet fuel

RMIT researchers have developed a carbon conversion technology that may one day help turn industrial emissions into jet fuel, by simplifying how carbon dioxide is recycled.