In 1915, a Russian chemist invented the world’s first gas mask using activated charcoal to filter toxic gases. Surprisingly, the basics of gas mask technology haven’t shifted much since then.

While more functional than those first used in World War I, modern gas masks still rely on canisters that are limited in their effectiveness, offering little protection from common chemicals like chlorine and ammonia.

In 2017, the Department of Defence called for the development of new state-of-the-art gas mask technology for Australian soldiers.

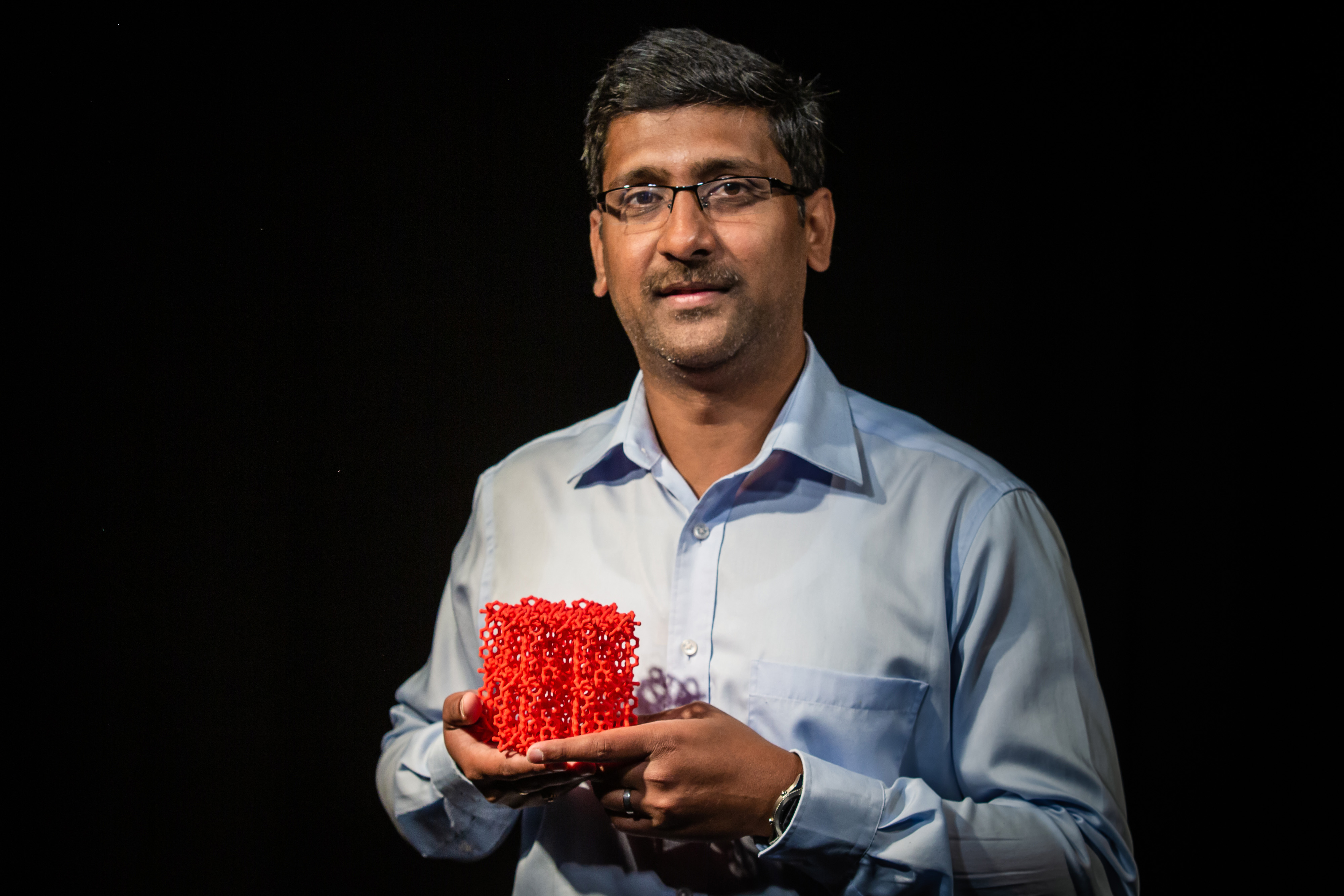

RMIT University materials engineer Dr Ravichandar Babarao is the computational wizard on the project, a collaboration with CSIRO and Monash University.

His role? Giving the experimental scientists something solid to work with, by narrowing down thousands of potential materials to a shortlist of those best suited for the job.

With his computational modelling, Babarao can do in months what could take decades to complete in a lab.

“We’re working with Metal-Organic Frameworks, or MOFs, which are incredibly porous materials that can be used to store, separate, release or protect almost anything,” said Babarao, an ARC DECRA Fellow in RMIT’s School of Science and a CSIRO Visiting Scientist.

“MOFs were first developed about 20 years ago but scientists have created more than 88,000 types since then, all with slightly different qualities.

“Testing each one to see if they’d work for a particular application would take years of trial and error.

“By running all the MOFs through a computer simulation first, we can identify the select few to focus on and radically shrink the time it takes to get from experiment to finished product.”

Porous and flexible: why MOFs are so special

Metal-Organic Frameworks are crystal structures crammed full of molecular-sized holes.

They’re so incredibly porous that if you could take a gram of a MOF and spread out its internal surface area, you would cover an entire cricket ground.

They’re also customisable and flexible, making them ideal for developing materials that can sense and capture substances at minute concentrations; purify water to remove heavy metals, oils or toxins; store gases more safely; separate gases or liquids more effectively; or protect biomolecules in harsh environments.