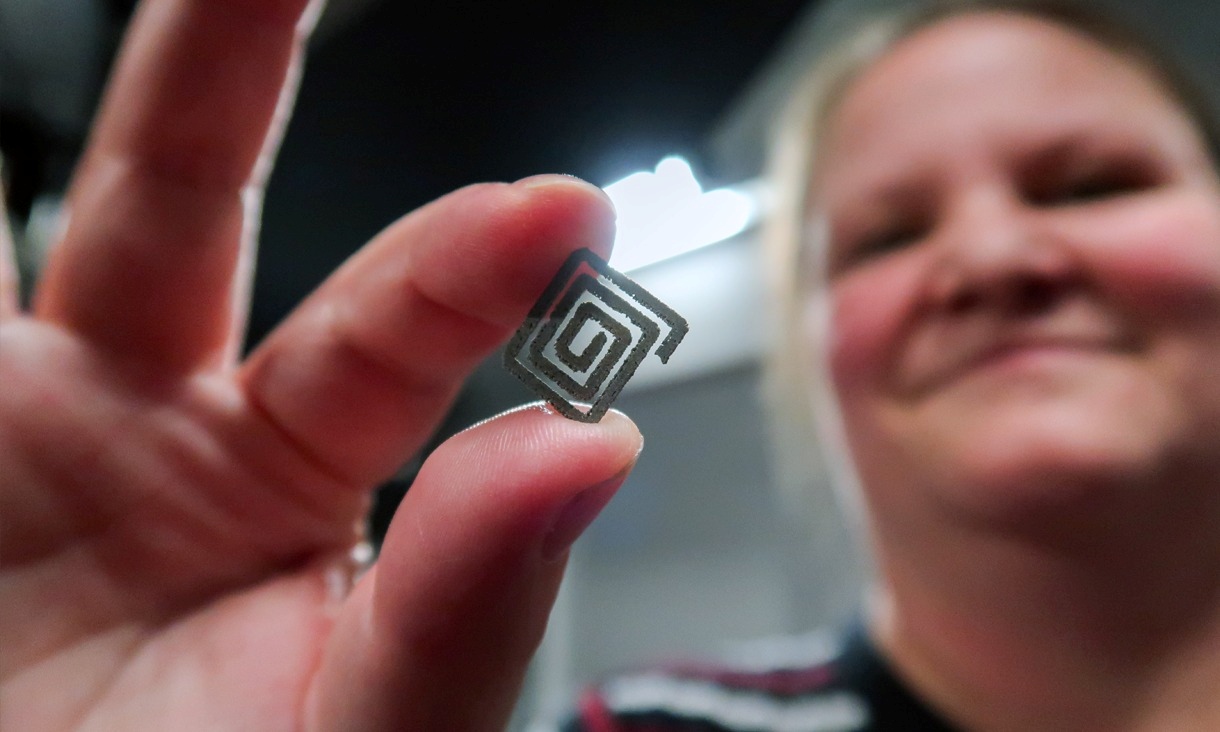

‘Incredibly resilient’ nylon device creates electricity under tonnes of pressure

RMIT University researchers have developed a flexible nylon-film device that generates electricity from compression and keeps working even after being run over by a car multiple times, opening the door to self-powered sensors on our roads and other electronic devices.

Indigenous plant could have handy health benefits

New research suggests an Australian desert plant could help food manufacturers improve protein quality and reduce reliance on added salt in staple foods.

European research lays the groundwork for future stem cell clinical trials

RMIT has contributed to an international consortium exploring how human mesenchymal stem cells could help to repair brain injury in children born preterm.

Aussie bushfire prevention tech goes global

A powerline fault detection system invented at RMIT is being rolled out globally thanks to AUD $50 million in new funding.