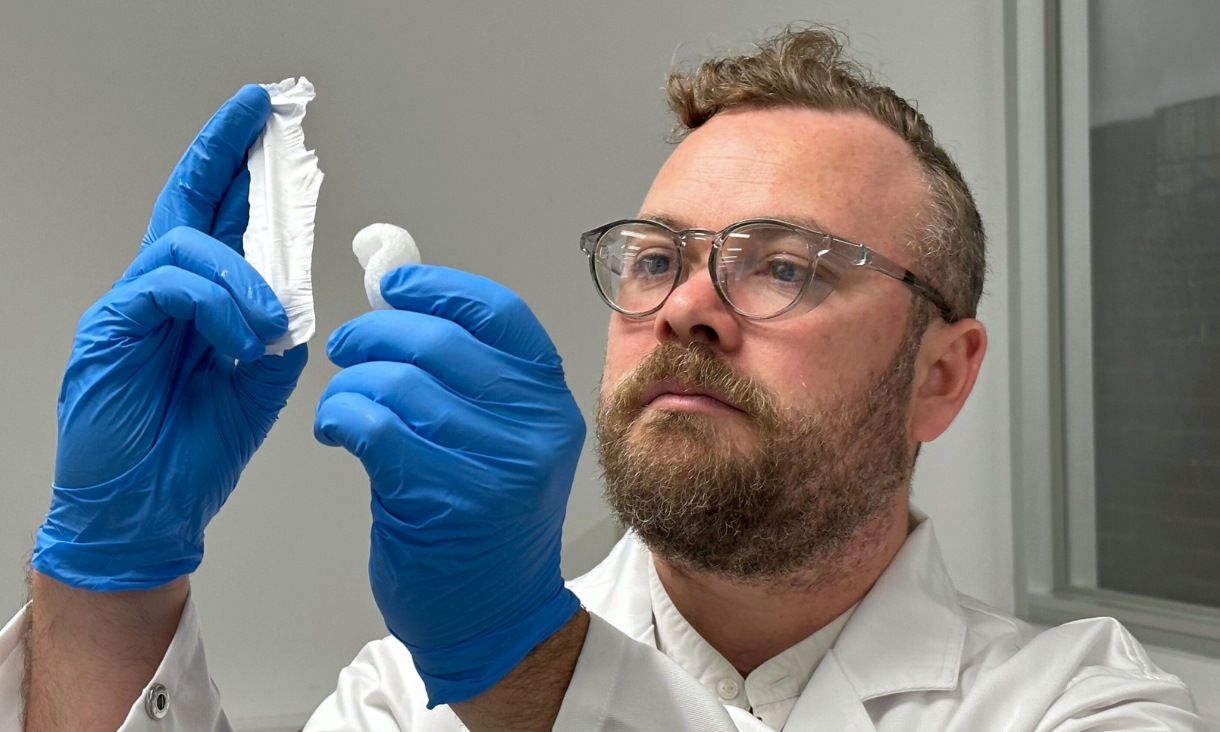

The spray-on coatings developed by researchers at RMIT are ultra-thin, cost-effective and rival the performance of current industry standards for transparent electrodes.

Combining the best properties of glass and metals in a single component, a transparent electrode is a highly conductive clear coating that allows visible light through.

The coatings - key components of technologies including smart windows, touchscreen displays, LED lighting and solar panels - are currently made through time-consuming processes that rely on expensive raw materials.

The new spray-on method is fast, scalable and based on cheaper materials that are readily available.

The method could simplify the fabrication of smart windows, which can be both energy-saving and dimmable, as well as low-emissivity glass, where a conventional glass panel is coated with a special layer to minimise ultraviolet and infrared light.

Lead investigator Dr Enrico Della Gaspera said the pioneering approach could be used to substantially bring down the cost of energy-saving windows and potentially make them a standard part of new builds and retrofits.

“Smart windows and low-E glass can help regulate temperatures inside a building, delivering major environmental benefits and financial savings, but they remain expensive and challenging to manufacture,” said Della Gaspera, a senior lecturer and Australian Research Council DECRA Fellow at RMIT.

“We’re keen to collaborate with industry to further develop this innovative type of coating.

“The ultimate aim is to make smart windows much more widely accessible, cutting energy costs and reducing the carbon footprint of new and retrofitted buildings.”

The new method can also be precisely optimised to produce coatings tailored to the transparency and conductivity requirements of the many different applications of transparent electrodes.