You are much more likely to be thinking about the day ahead, but these rails and how well your seat moves on them are an important part of how happy you are with your car.

RMIT's Dr Martin Leary has worked with industry partner Futuris Automotive on automotive seat optimisation.

Futuris designs and manufactures automotive interior components including seat systems and seat hardware.

Leary says that although car seats have been made for more than 100 years, there is still plenty of opportunity for innovation.

"Once a design has been rolled out, it will stay in use for as long as possible to keep manufacturing costs economically viable, so it is imperative that the design process is supported by smart engineering."

RMIT's Applied Optimisation Group, which Leary leads, worked with Futuris on a variety of research projects related to automotive products and processes.

Engineering Manager, Seating Structures, at Futuris, Tony Baxter, says working with RMIT has been extremely beneficial to both parties.

"It has enabled us to pursue novel, difficult and time-consuming developments that we would not have otherwise had the resources, including the intellectual resources, to deliver."

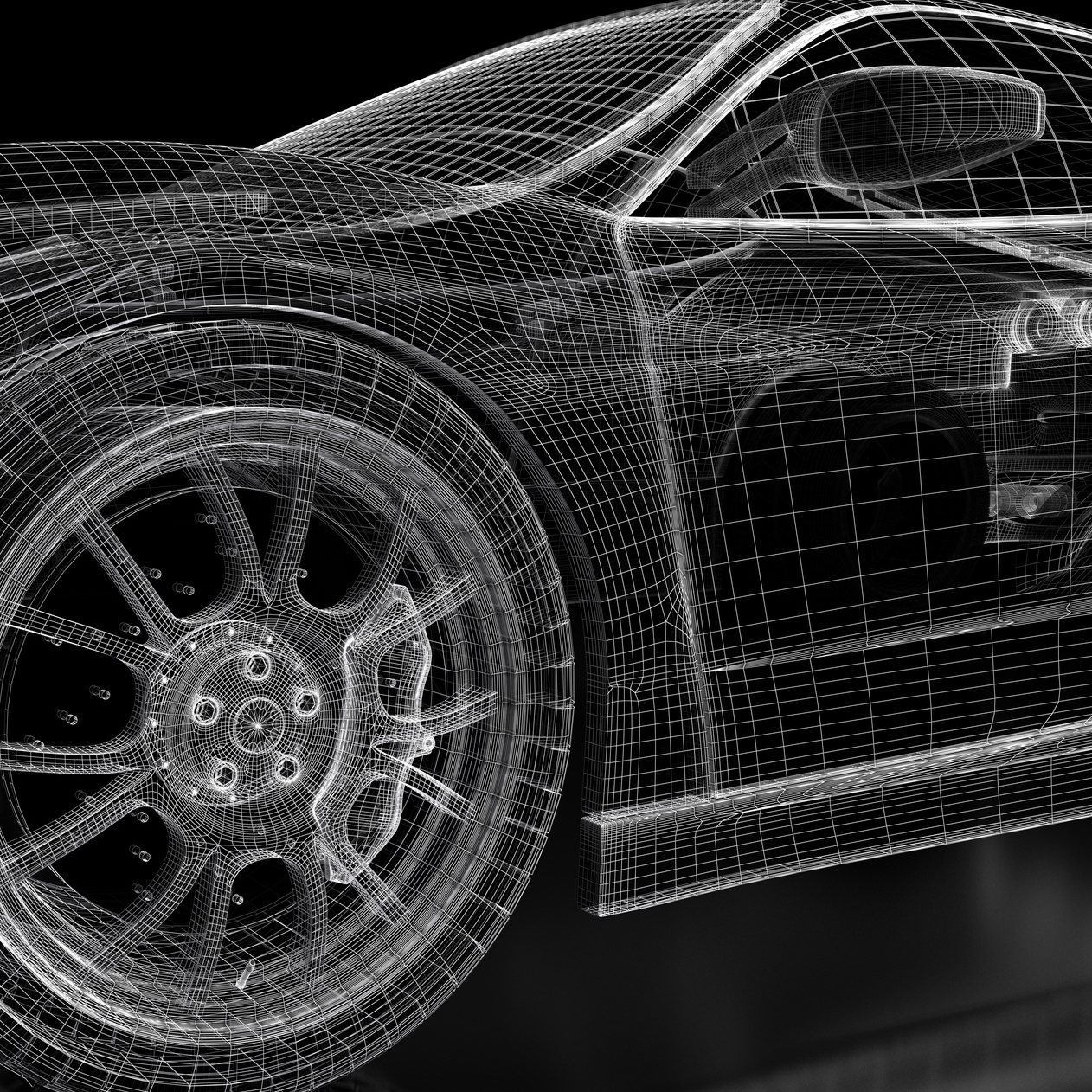

But back to the seat, which is a very stylish car seat for the American Tesla Model S high-performance electric vehicle.

Baxter says: "Within the Tesla Model S seat system, which we have designed and are now supplying, mass optimisation is critical - but this has to be without compromise to the very high level of comfort, safety and functionality required by the American consumer.

"The seating system will be fully articulated and electronically powered. The motors and gearboxes that drive the seat kinematics (movement between points) are heavy and this weight poses a considerable problem."