We are developing the next generation of engineers, designers and technicians, and working closely with industry both in Australia and internationally. Our vision is to be the leader in the implementation of the next wave of manufacturing in Australia.

Our specialised equipment and experts can assist companies to develop new conceptual products, perform multiple design iterations, or further develop existing products or enhance existing manufacturing processes.

We offer:

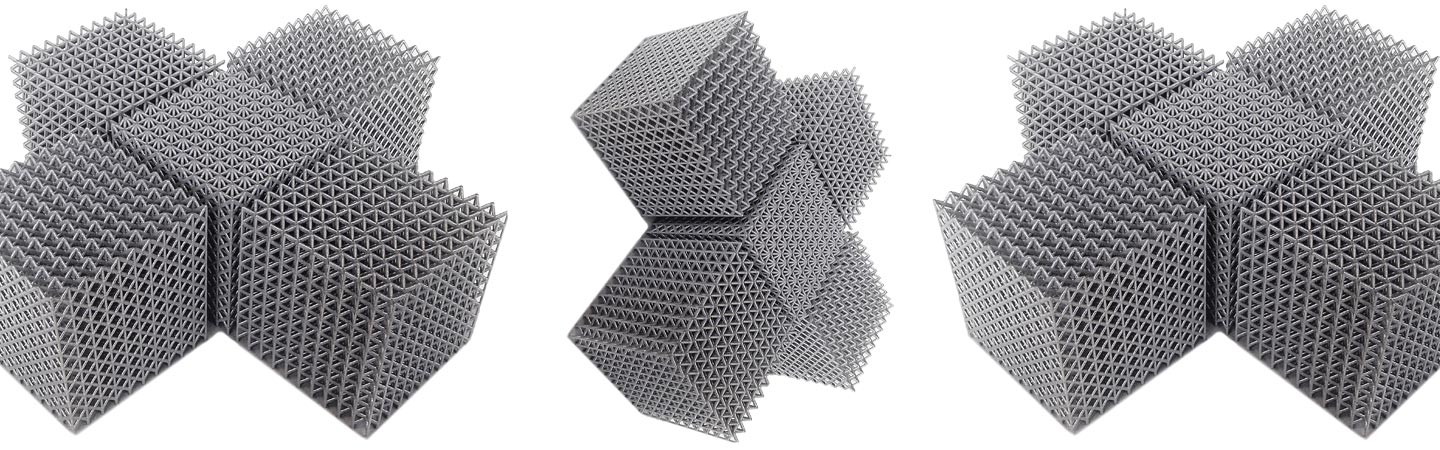

Housing some of the most advanced manufacturing technologies available, the Advanced Manufacturing Precinct brings design and engineering together, from digital design to digital manufacturing. We focus in particular on 3D printing of advanced high value add products and components.

We can build final products direct from a computer model in both polymers and high-tech metal alloy powders.

We house internationally recognised multi-axis CNC machines for machining high-performance alloys and composites for engineering applications.

We use a range of automation robotics to simulate manufacturing production lines used in the furniture, textile and design industries.

We can build final products direct from a computer model in both polymers and high-tech metal alloy powders. Our state-of-the-art additive manufacturing technologies include:

The Advanced Manufacturing Precinct houses internationally recognised multi-axis CNC machines (Okuma and Haas) for machining high-performance alloys and composites for engineering applications.

Robotic technology gives our subtractive manufacturing capability greater diversity and flexibility of applications. We use a range of automation robotics to simulate manufacturing production lines used in the furniture, textile and design industries. We have the latest in CAD software, allowing students and researchers to design components and models.

The Advanced Manufacturing Precinct works with industry in a number of different ways.

Most notably we engage in:

Although the Advanced Manufacturing Precinct offers access to technology and equipment that can speed up prototyping and manufacture processes, the partnerships we form with industry are generally much richer. Production of a prototype part is usually only the start of the relationship, as most lead to developing an understanding of the form and functionality and assurance of scaling to mass production.

Partnerships with industry often involve collaboration with other areas of RMIT’s capabilities, creating a conduit to access many experts and disciplines in the University.

We offer commercial applications across a broad range of industries, including:

Engineers from RMIT University have produced a new type of 3D-printed titanium that’s about a third cheaper than commonly used titanium alloys.

Engineers at RMIT University have invented a small ‘neuromorphic’ device that detects hand movement, stores memories and processes information like a human brain, without the need for an external computer.

Engineers from Australia and China have invented a sponge-like device that captures water from thin air and then releases it in a cup using the sun’s energy, even in low humidity where other technologies such as fog harvesting and radiative cooling have struggled.

Inspired by the humble deep-sea sponge, RMIT University engineers have developed a new material with remarkable compressive strength and stiffness that could improve architectural and product designs.

Address: 58 Cardigan Street, Carlton, Victoria, 3083

Location: Melbourne City campus

Email: amp@rmit.edu.au

Phone: +61 3 9925 4197

Professor Milan Brandt - Technical Director

Advanced Manufacturing Precinct RMIT University

GPO Box 2476

Melbourne 3001 Victoria

The RMIT Centre for Additive Manufacturing (RCAM) is a pioneering, multi-disciplinary research centre dedicated to advancing industrial additive manufacturing technologies.

Our cutting-edge facilities represent our commitment to developing world-class learning, teaching, training and research spaces.

Together with our partners and donors, we develop and apply knowledge to shape a better world.

RMIT University acknowledges the people of the Woi wurrung and Boon wurrung language groups of the eastern Kulin Nation on whose unceded lands we conduct the business of the University. RMIT University respectfully acknowledges their Ancestors and Elders, past and present. RMIT also acknowledges the Traditional Custodians and their Ancestors of the lands and waters across Australia where we conduct our business - Artwork 'Sentient' by Hollie Johnson, Gunaikurnai and Monero Ngarigo.

Learn more about our commitment to Indigenous cultures