Potential applications

The team’s innovation could one day improve response times of automated vehicles and advanced robotic systems to visual information, which could be crucial particularly in dangerous and unpredictable environments.

“Neuromorphic vision in these applications, which is still many years away, could detect changes in a scene almost instantly, without the need to process lots of data, enabling a much faster response that could save lives,” Walia said.

“For robots working closely with humans in manufacturing or as a personal assistant, neuromorphic technology could enable more natural interactions by recognising and reacting to human behaviour with minimal delay,” Al-Hourani said.

Next steps

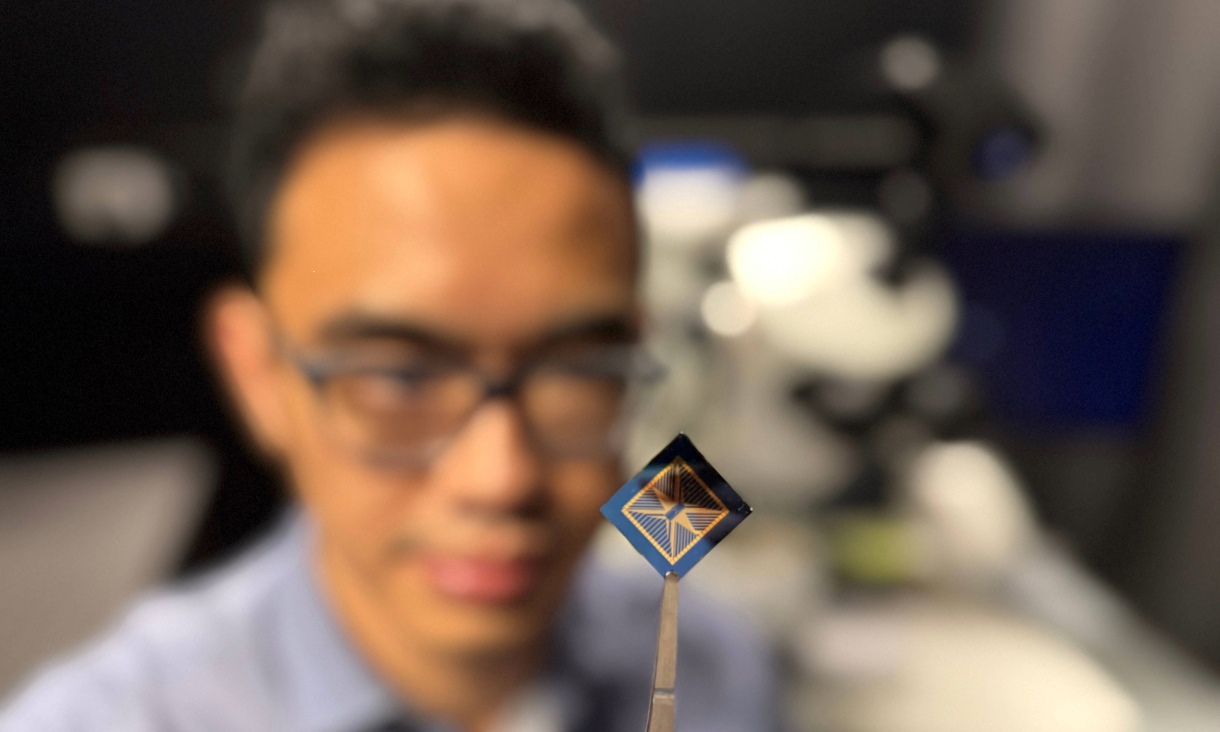

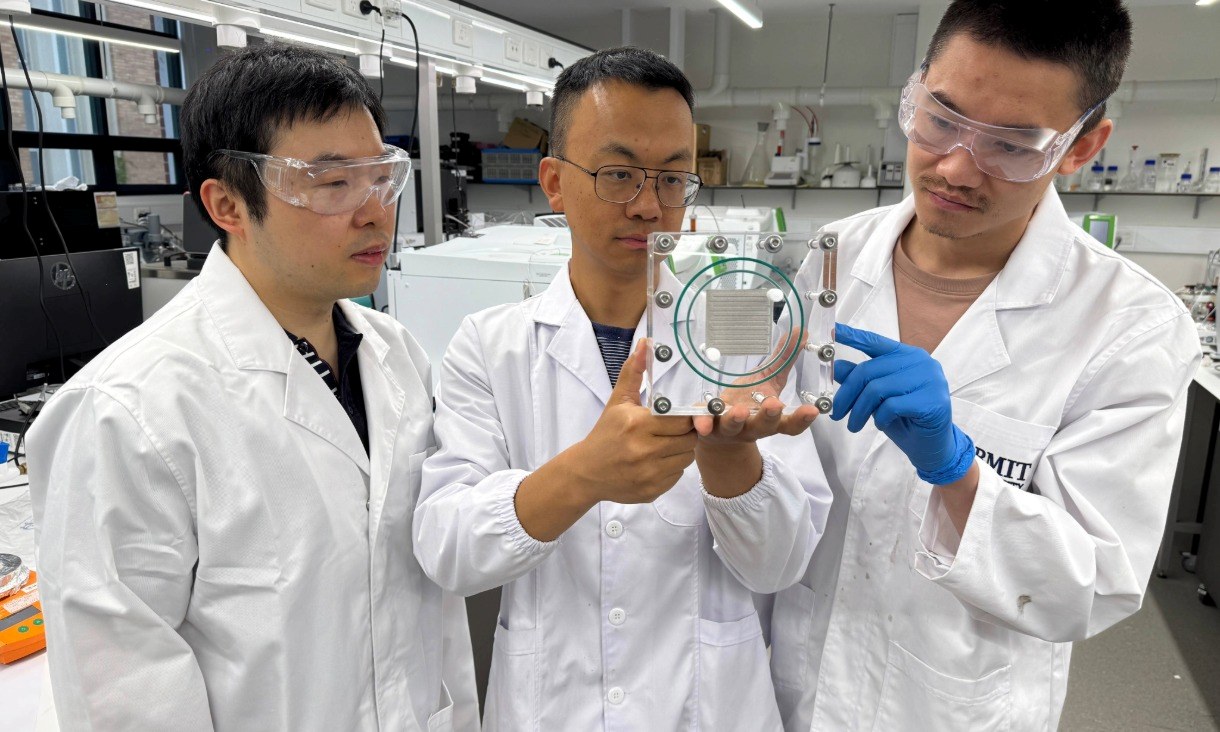

The team is now scaling up the proof-of-concept single-pixel device to a larger pixel array of MoS2-based devices.

The Australian Research Council has recently funded the team with a Linkage Infrastructure, Equipment and Facilities (LIEF) grant to enable this scaling up of their neuromorphic devices.

“While our system mimics certain aspects of the brain’s neural processing, particularly in vision, it's still a simplified model,” Walia said.

"We will optimise the devices to perform specific real-world applications with more complex vision tasks, and further reduce power consumption."

The team plans to develop hybrid systems that integrate their analogue technology with conventional digital electronics.

“We see our work as complementary to traditional computing, rather than a replacement,” Walia said.

“Conventional systems excel at many tasks, while our neuromorphic technology offers advantages for visual processing where energy efficiency and real-time operation are critical.”

The team is also investigating materials other than MoS2 that might extend capabilities into infrared, which could enable real-time tracking of global emissions and intelligent sensing of contaminants such as toxic gases, pathogens and chemicals.

‘Photoactive monolayer MoS2 for spiking neural networks enabled machine vision applications’ is published in Advanced Materials Technologies (DOI: 10.1002/admt.202401677).

Story: Will Wright