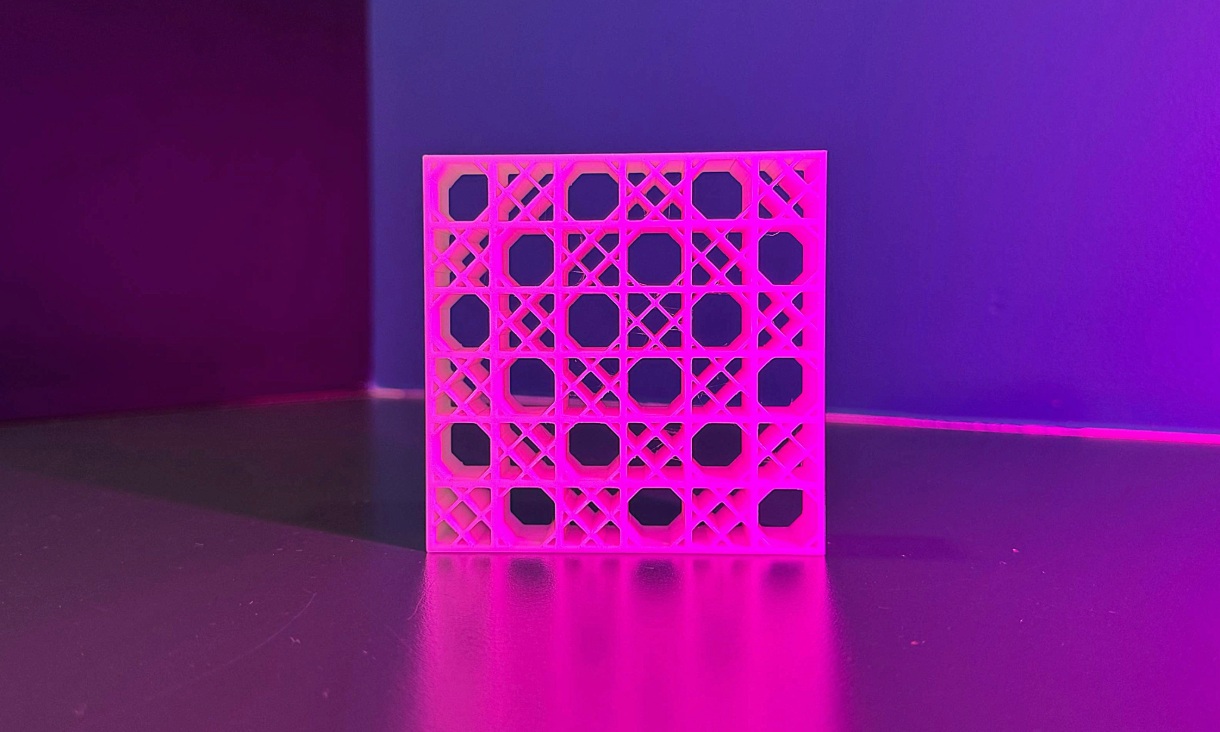

Sea sponge inspires super strong compressible material

Inspired by the humble deep-sea sponge, RMIT University engineers have developed a new material with remarkable compressive strength and stiffness that could improve architectural and product designs.

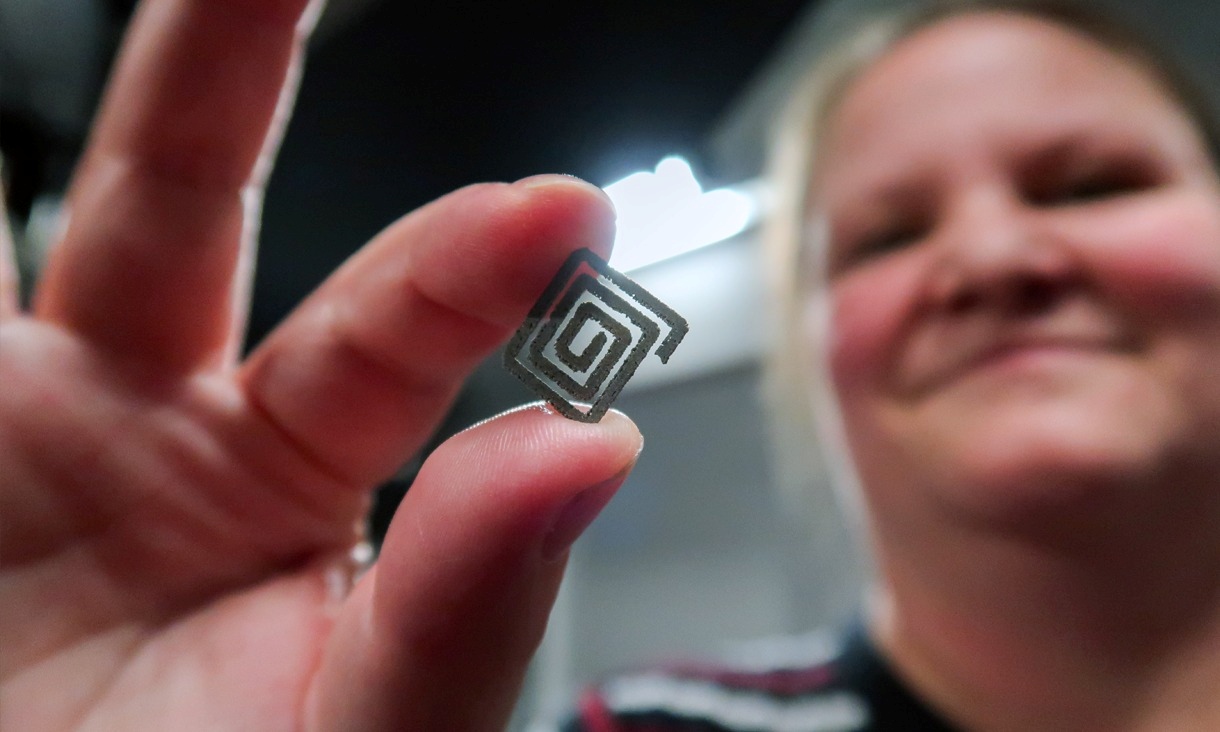

Diamond power could be a medical implant’s best friend

RMIT researchers have created an experimental 3D-printed diamond–titanium device that generates electricity from flowing liquid and receives wireless power through tissue making it possible to remotely sense changes in flow.

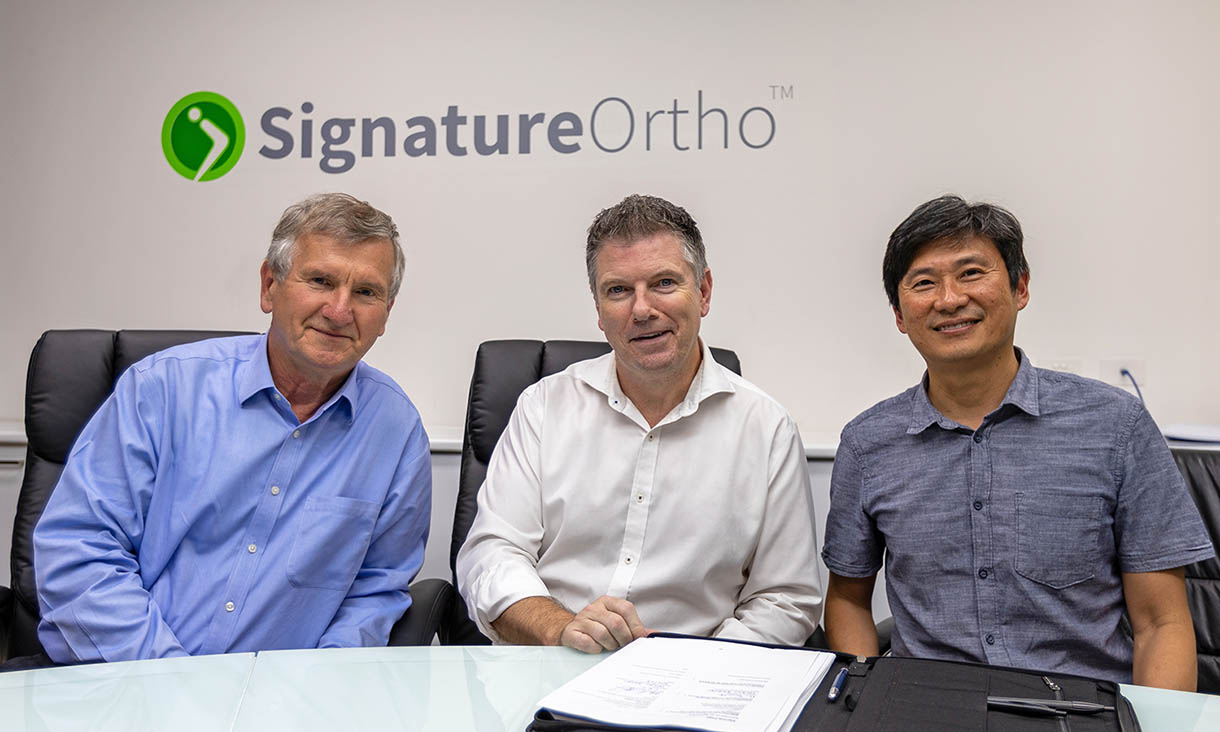

New industry-research partnership accelerates Medtech innovation in Melbourne

Australian medical device company Signature Orthopaedics is partnering with leading Medtech researchers at the University of Melbourne and RMIT University.

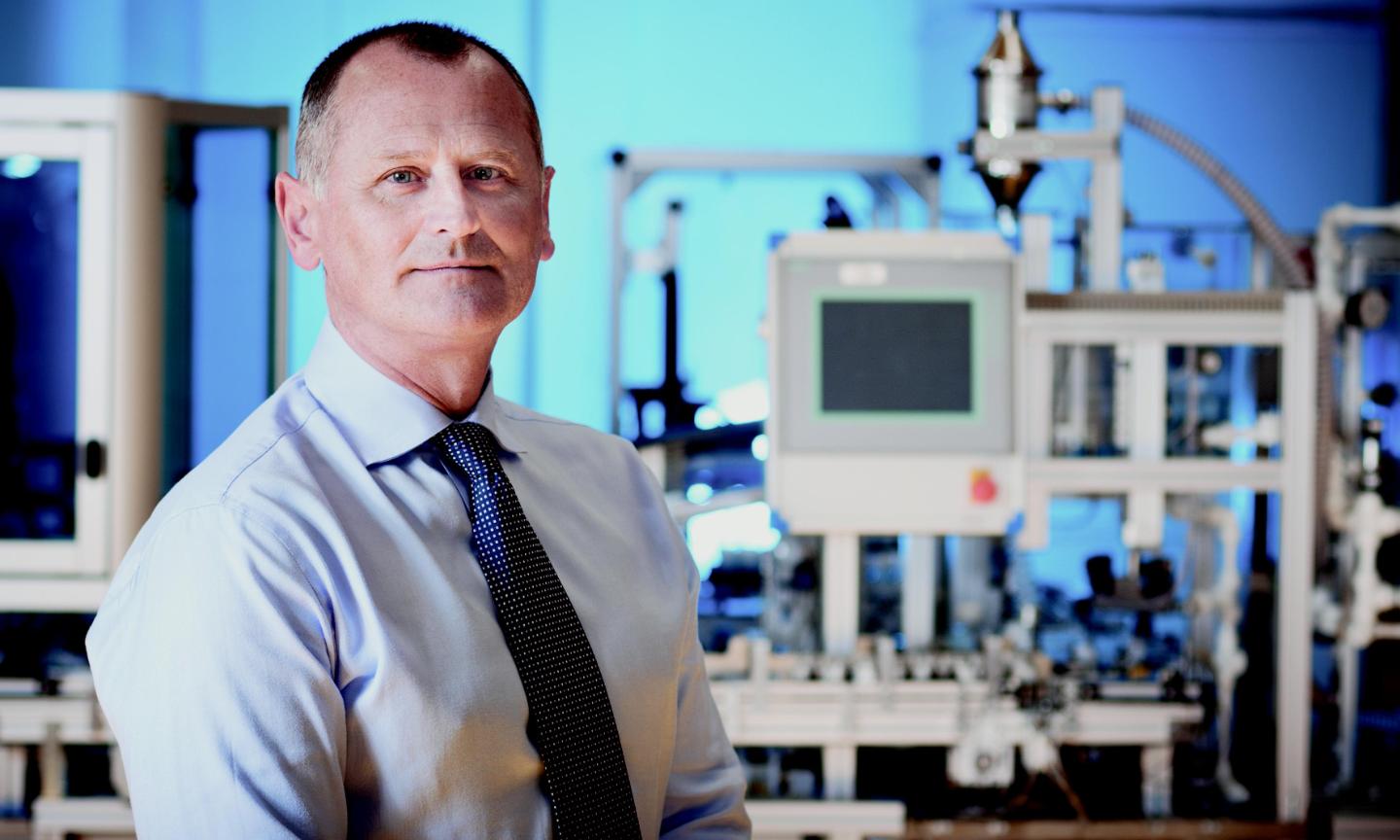

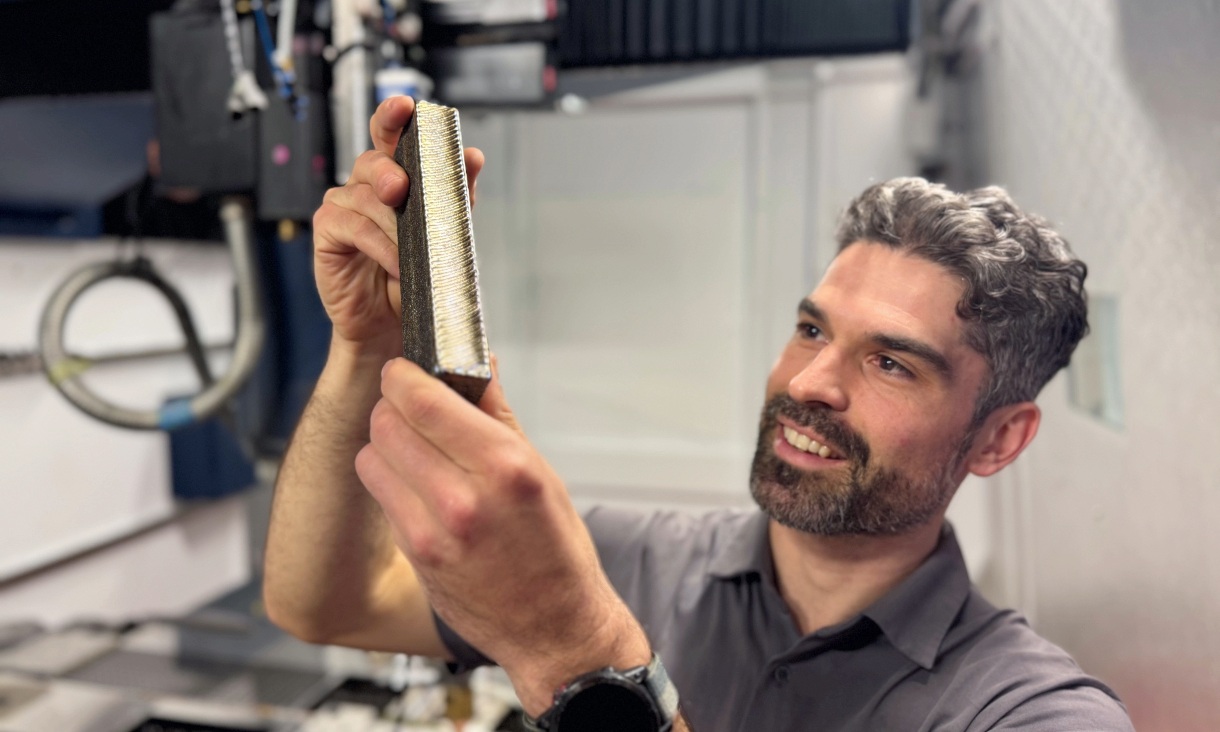

Stronger, cheaper titanium a 'leap forward' for industry

Engineers from RMIT University have produced a new type of 3D-printed titanium that’s about a third cheaper than commonly used titanium alloys.