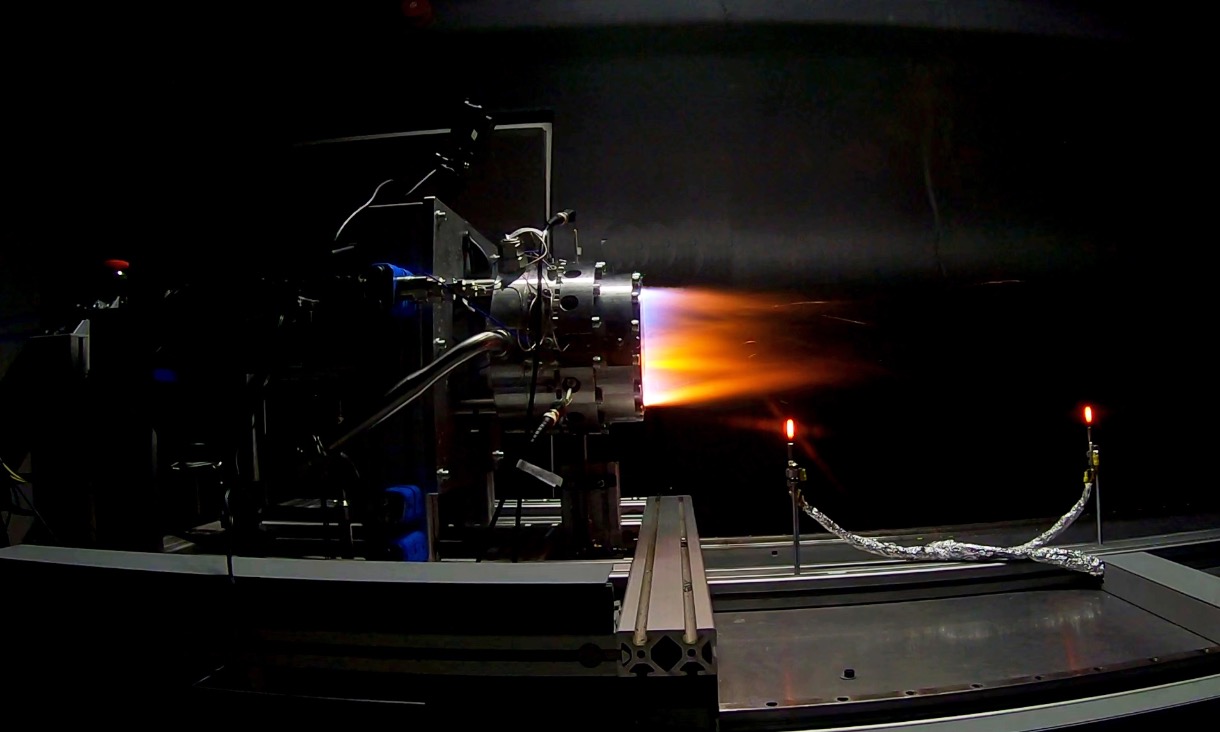

The team plans to further refine the material for maximum efficiency and explore applications in higher-temperature environments.

While currently resistant to temperatures as high as 350 °C, they believe it could be made to withstand temperatures up to 600 °C using more heat-resistant titanium alloys, for applications in aerospace or firefighting drones.

As the technology to make this new material is not yet widely available, its adoption by industry might take some time.

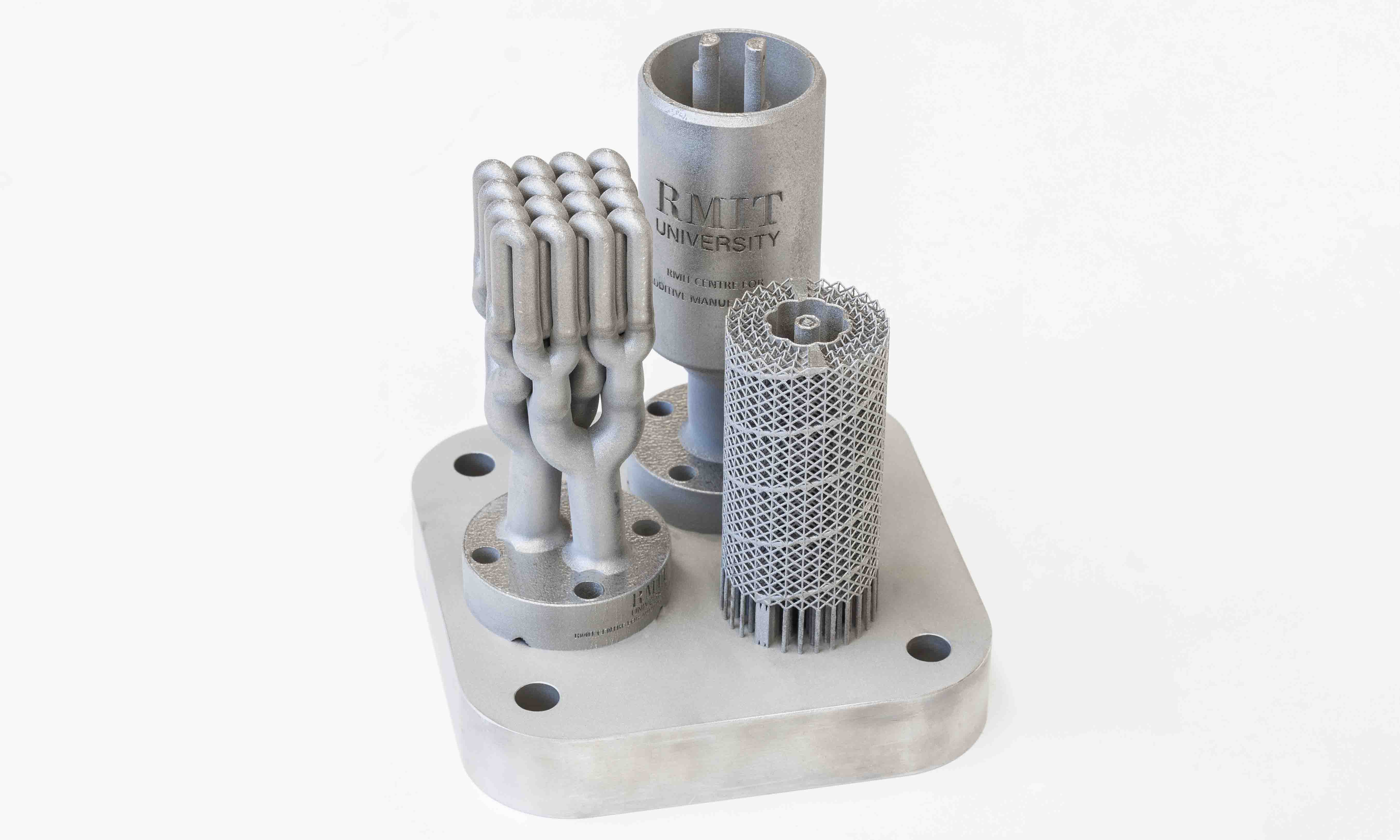

“Traditional manufacturing processes are not practical for the fabrication of these intricate metal metamaterials, and not everyone has a laser powder bed fusion machine in their warehouse,” he said.

“However, as the technology develops, it will become more accessible and the printing process will become much faster, enabling a larger audience to implement our high-strength multi-topology metamaterials in their components. Importantly, metal 3D printing allows easy net shape fabrication for real applications.”

Technical Director of RMIT's Advanced Manufacturing Precinct, Distinguished Professor Milan Brandt, said the team welcomed companies wanting to collaborate on the many potential applications.

“Our approach is to identify challenges and create opportunities through collaborative design, knowledge exchange, work-based learning, critical problem-solving and translation of research,” he said.

‘Titanium Multi-Topology Metamaterials with Exceptional Strength’ was published in Advanced Materials (DOI: 10.1002/adma.202308715).

The authors acknowledge the scientific and technical support of the RMIT Advanced Manufacturing Precinct and the RMIT Microscopy and Microanalysis Facility, especially the technical staff Simon Brudler and Paul Spithill. The project was funded by the Australian Research Council.

Story: Michael Quin