Diamond power could be a medical implant’s best friend

RMIT researchers have created an experimental 3D-printed diamond–titanium device that generates electricity from flowing liquid and receives wireless power through tissue making it possible to remotely sense changes in flow.

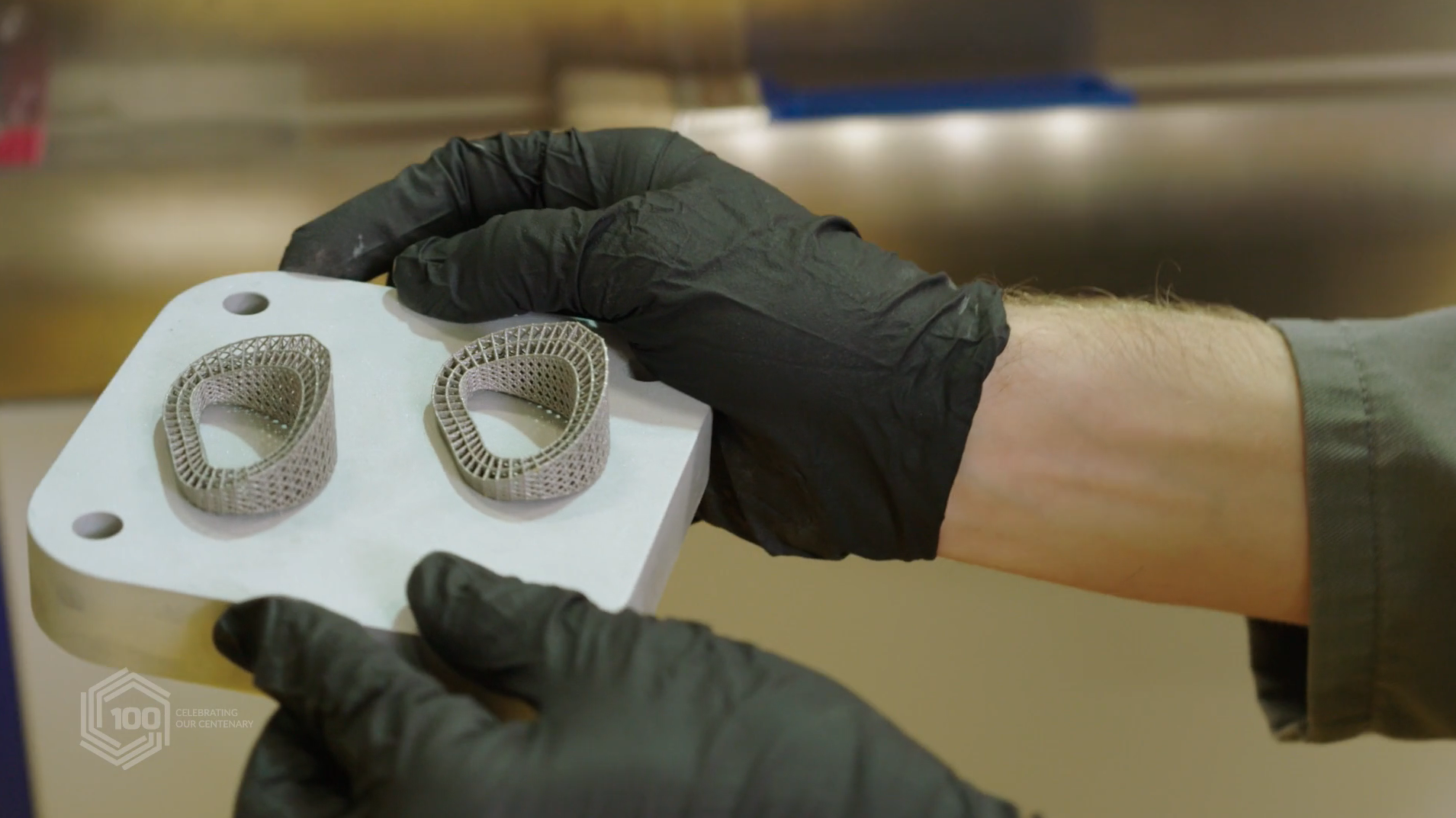

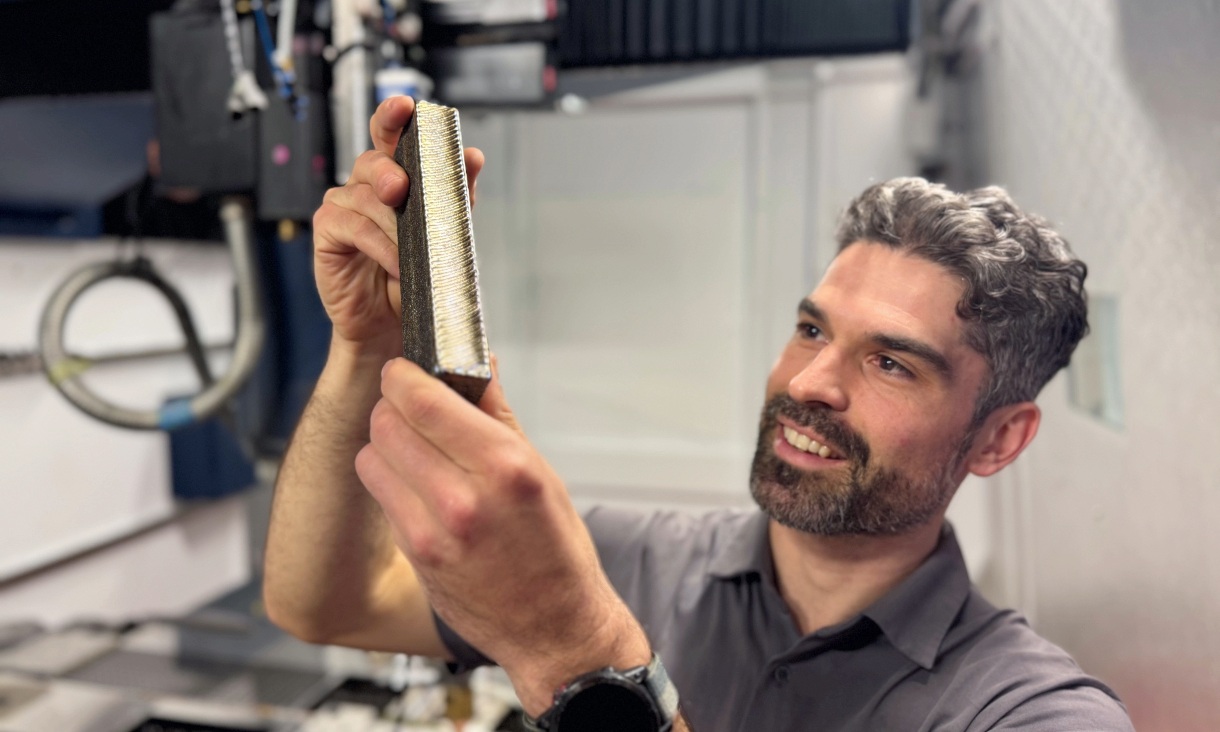

Stronger, cheaper titanium a 'leap forward' for industry

Engineers from RMIT University have produced a new type of 3D-printed titanium that’s about a third cheaper than commonly used titanium alloys.

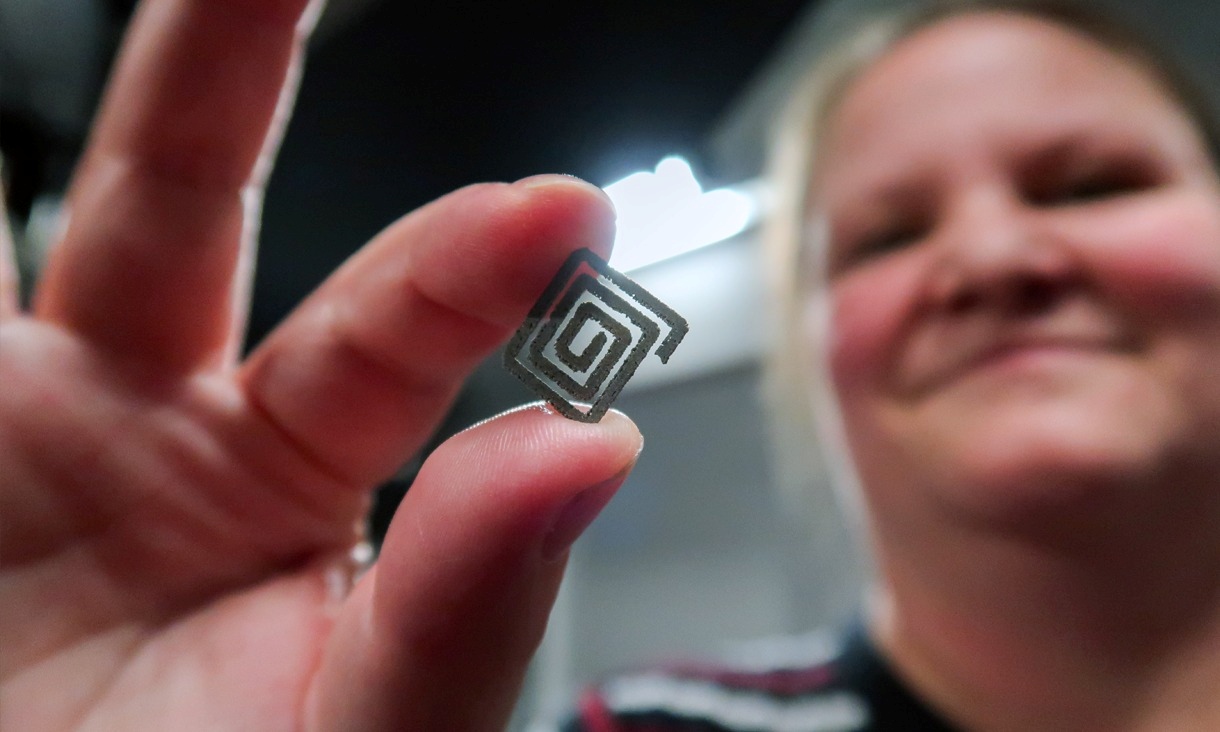

Tiny device promises new tech with a human touch

Engineers at RMIT University have invented a small ‘neuromorphic’ device that detects hand movement, stores memories and processes information like a human brain, without the need for an external computer.

Smart spongy device captures water from thin air

Engineers from Australia and China have invented a sponge-like device that captures water from thin air and then releases it in a cup using the sun’s energy, even in low humidity where other technologies such as fog harvesting and radiative cooling have struggled.