Shrinivas Kulkarni

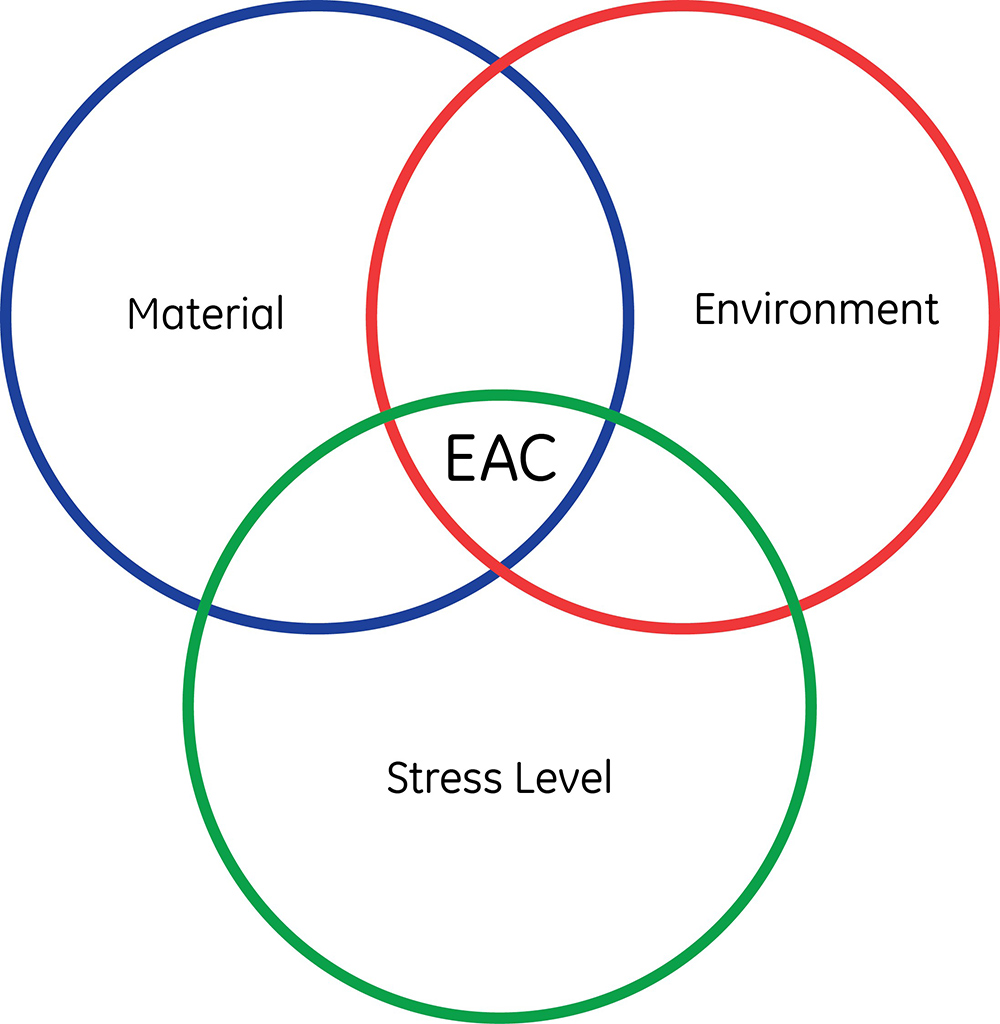

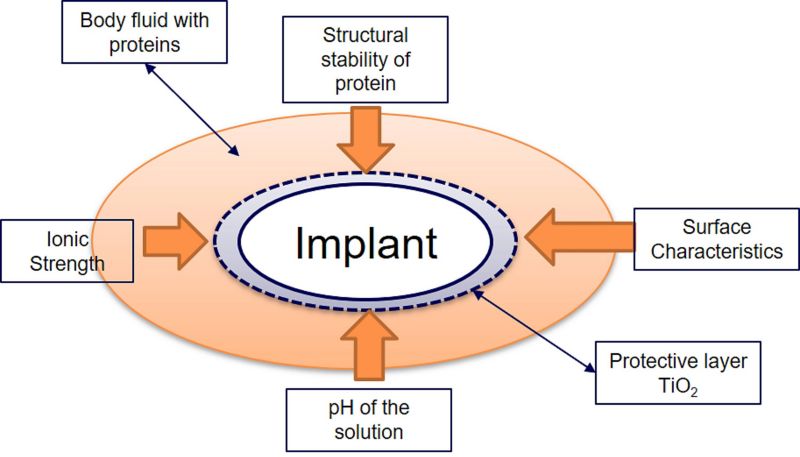

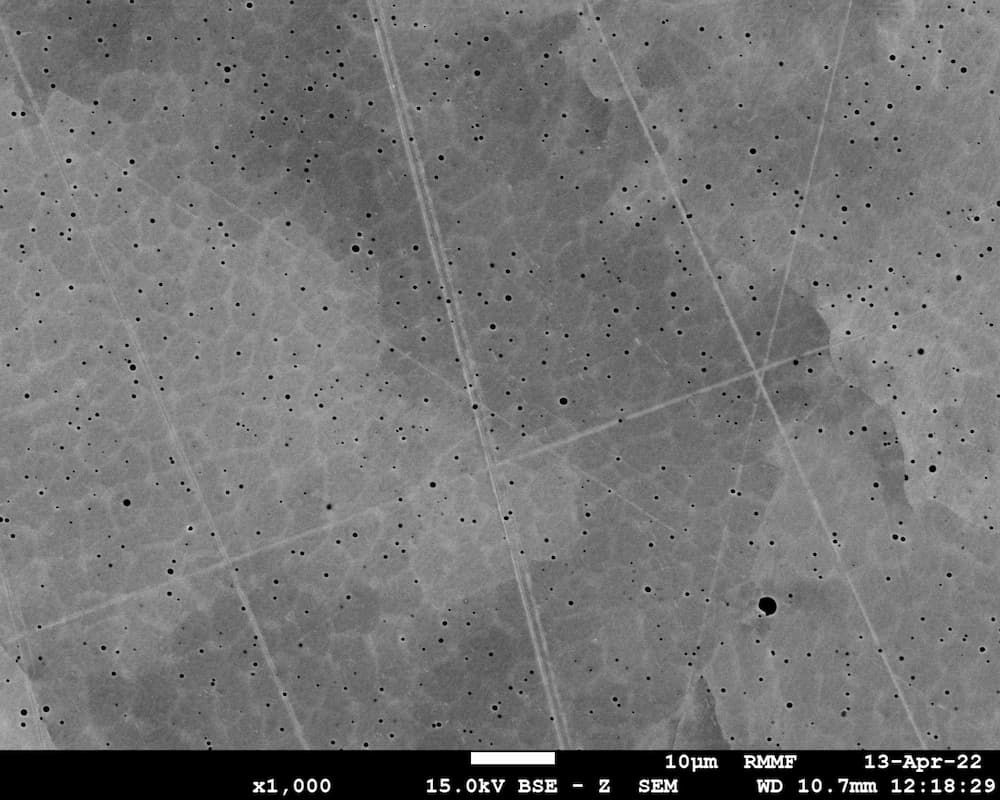

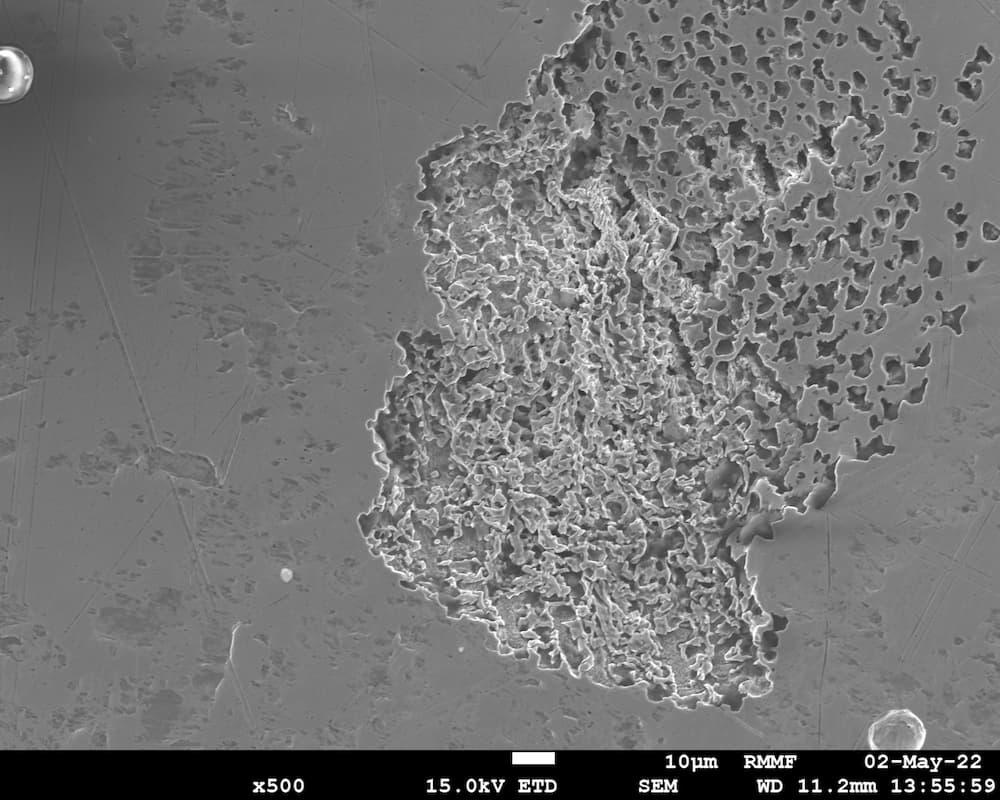

I’m Shrini, a third year PhD research student at RMIT University. My research is focused on the environmentally assisted corrosion (EAC) or stress corrosion cracking (SCC) of additively manufactured (AM) passive metals as described elsewhere [1]. EAC (Figures 1 & 2) is a combined consequence of an implant’s physiological environment, externally imposed stresses, and material physicochemical properties on implant performance & lifetime. Coupon samples of AM stainless steel 316L (SS316L) and titanium-aluminium 6wt%-vanadium 4wt% (Ti6Al4V) will be produced using the Selective Laser Melting (SLM) & Electron Beam Melting (EBM) processes. Surface characteristics including roughness and AM process-related defects including porosity, cracks, and segregation will be characterised to determine their effect on corrosion pit nucleation and pit-to-crack transition (Figure 3). The aim is to establish the relationship between surface/microstructure and the life of commercial implant materials subjected to EAC and cyclical loading leading to fatigue. Corrosion, SCC, and fatigue testing will be conducted in both NaCl solution & simulated body fluid (SBF). The results will be analysed for stress concentration factor at pits and implant lifetime. This study will be critical for lattice-structured AM implants as they are difficult to postprocess considering the size of individual lattice elements (Figure 4).

Figure 1: Factors with influence on environmentally assisted corrosion

Figure 1: Factors with influence on environmentally assisted corrosion

Figure 3: AM SS316L surface (a) before, and (b) after corrosion in 3.5 wt.% NaCl(aq) solution

References

[1] A Bandyopadhyay, BV Krishna, WX, and S Bose (2009). ‘Application of Laser Engineered Net Shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants’, Journal of Materials Science: Materials in Medicine, vol. 20, no. S1, pp. 29-34, DOI: 10.1007/s10856-008-3478-2.

[2] M Talha, Y Ma, P Kumar, Y Lin, and A Singh (2019). ‘Role of protein adsorption in the bio corrosion of metallic implants – A review’, Colloids & Surfaces B: Biointerfaces, vol. 176, pp. 494-506, DOI: 10.1016/j.colsurfb.2019.01.038.

[3] XZ Zhang, M Leary, HP Tang, T Song, and M Qian (2018). ‘Selective electron beam manufactured Ti-6Al-4V lattice structures for orthopedic implant applications: Current status and outstanding challenges’, Current Opinion in Solid State & Materials Science, vol. 22, no. 3, pp. 75-99, DOI: 10.1016/j.cossms.2018.05.002.

Corrosion and Inhibition

Corrosion inhibitors, corrosion of steel pipes in a soil environment, photocatalysts for CO2 hydrogenation, nano-sensing, optical sensing.