Aaqil Sameem - ALUMNUS

ALUMNUS – Current LinkedIn profile including contact details.

Conventional cutting tools are made from high-carbon steel, high-speed steel, cemented carbides and diamonds. These tools must be able to withstand high temperatures and mechanical loads caused by friction against the workpiece. However, common metallurgical knowledge is that very hard materials are brittle and thus have low toughness and break more easily, particularly at high temperatures. One of the commonest materials used for cutting tools is cemented carbides due to their excellent mechanical properties. These are metal-matrix composites (MMC) in which the carbide particles are a solid aggregate within the metallic binder/matrix. During the life of a cutting tool, the cutting edge wears out more quickly than the tool base. Once worn out, they are either discarded or recycled. Recycling of cemented carbides is difficult due to their superior hardness and very high melting temperature.

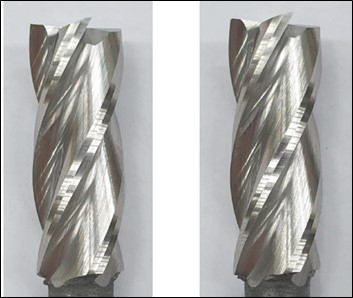

My research aims to rebuild the cutting edge on an existing tool base by using additive manufacturing methods such as DED. I will use of pre-alloyed powders with finely dispersed carbides as the AM feedstock to deliver a homogenous microstructure in the rebuilt tool edge. I will also vary AM process parameters (laser power, scan speed, powder flow rate) to obtain suitable microstructures, hardness values over 1100 HV0.5, and good wear performance. The results will then be compared to the characteristics of conventionally sintered carbides.

This project was conducted in conjunction with ANCA Pty Ltd and CSIRO.

This project has a patent pending.

Figure 1: ABB robot at CSIRO Clayton connected to laser optics

Figure 1: ABB robot at CSIRO Clayton connected to laser optics

Figure 2: Laser-cladded cutting tools on a steel shank

Figure 2: Laser-cladded cutting tools on a steel shank

Figure 3: Finished cutting tools after grinding to the desired geometry

Figure 3: Finished cutting tools after grinding to the desired geometry

Metal Fabrication

Cold spray, melt pool, friction stir welding, multifunctional coatings for biomedical Mg alloys, visual monitoring of metal powder