Sun Yeang Chew

Cold spray additive manufacturing (CSAM) technology exhibits a high potential for producing large-scale complex objects. However, ensuring product quality & process consistency is still a challenge due to the associated high-rate deposition and the lack of a real-time monitoring system. We believe that today's computer vision technology is capable of solving this problem, despite the limited scholarly literature in this area, i.e. no such literature has thus far reported a detailed analysis of the performance of 3D visually based sensors in a cold spray environment.

This research project will implement and analyse the existing 3D reconstruction algorithms and 3D vision-based sensors to discover their limitations within cold spray environments. Hence, we will deepen our understanding of the problem and develop improved solutions. This project will develop a heuristic approach to choosing sensors based on 3D reconstruction methods, modelling, simulation, and testing datasets.

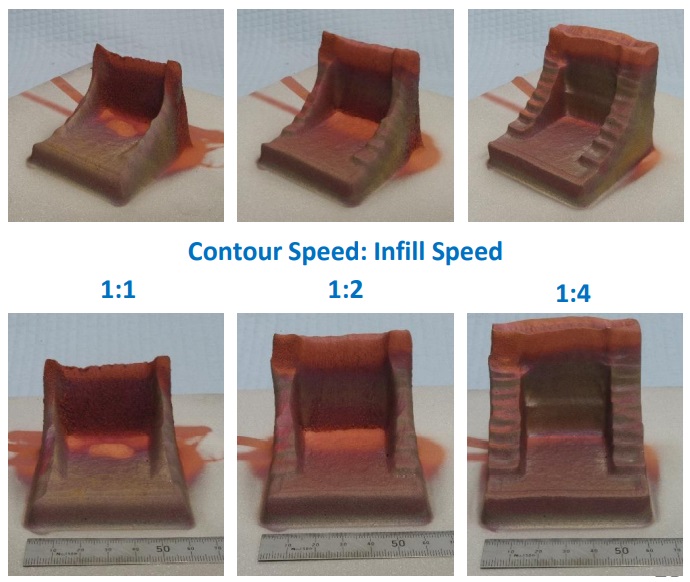

Figure 1: Toolpath planning case study of a square bracket [1]. Three samples were additively manufactured in copper using the same toolpath plan but with different ratios of contour speed to infill speed. The desired shape is barely (or not) achieved if this ratio of build parameter is incorrectly selected.

Figure 1: Toolpath planning case study of a square bracket [1]. Three samples were additively manufactured in copper using the same toolpath plan but with different ratios of contour speed to infill speed. The desired shape is barely (or not) achieved if this ratio of build parameter is incorrectly selected.

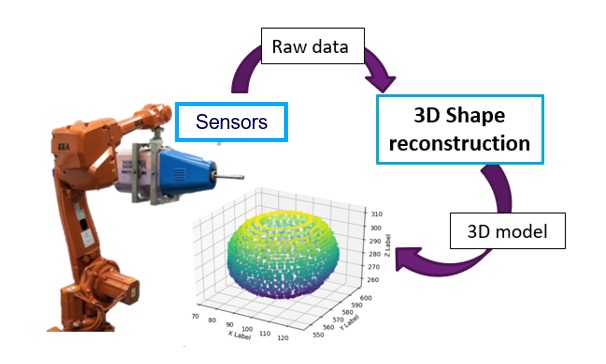

Figure 2: Block diagram of the 3D visualisation system used here for cold spray robotic additive manufacturing. A 3D visual sensor will be used to collect the geometric shape of printed object during the spraying process, after which a 3D reconstruction algorithm (e.g. SLAM) will reconstruct a 3D model from the raw sensor data.

Figure 2: Block diagram of the 3D visualisation system used here for cold spray robotic additive manufacturing. A 3D visual sensor will be used to collect the geometric shape of printed object during the spraying process, after which a 3D reconstruction algorithm (e.g. SLAM) will reconstruct a 3D model from the raw sensor data.

This project is conducted in conjunction with CSIRO.

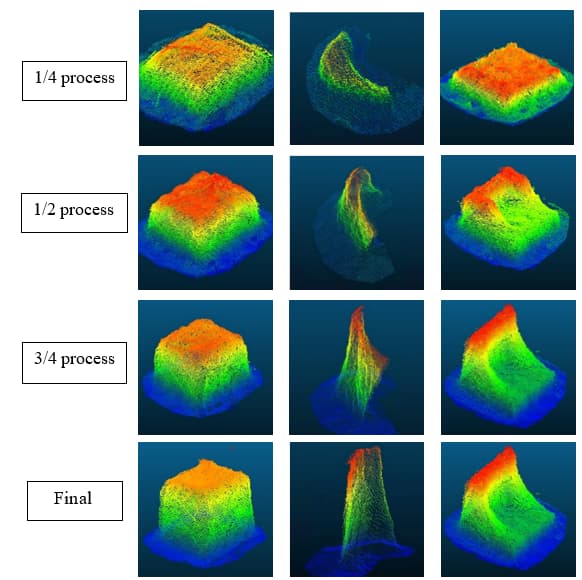

Figure 3: 3D reconstruction results obtained during the cold spray additive manufacturing process using the above-proposed method.

Figure 3: 3D reconstruction results obtained during the cold spray additive manufacturing process using the above-proposed method.

References

[1] A. Vargas-Uscategui and P.C. King. ‘Cold spray additive manufacturing of 3D objects using a continuous toolpath planning strategy’, Materials Innovations in Surface Engineering Conference (MISE2020), Melbourne (Australia), 11-12 February 2020.

Publications

SY Chew, E Asadi, A Vargas-Uscategui, PC King, A Bab-Hadiashar, I Cole (2022). ‘In-process 4D reconstruction for robotic additive manufacturing’, Robotics & Computer-Integrated Manufacturing, UNDER PREPARATION.

Metal Fabrication

Cold spray, melt pool, friction stir welding, multifunctional coatings for biomedical Mg alloys, visual monitoring of metal powder