Subash Gautam

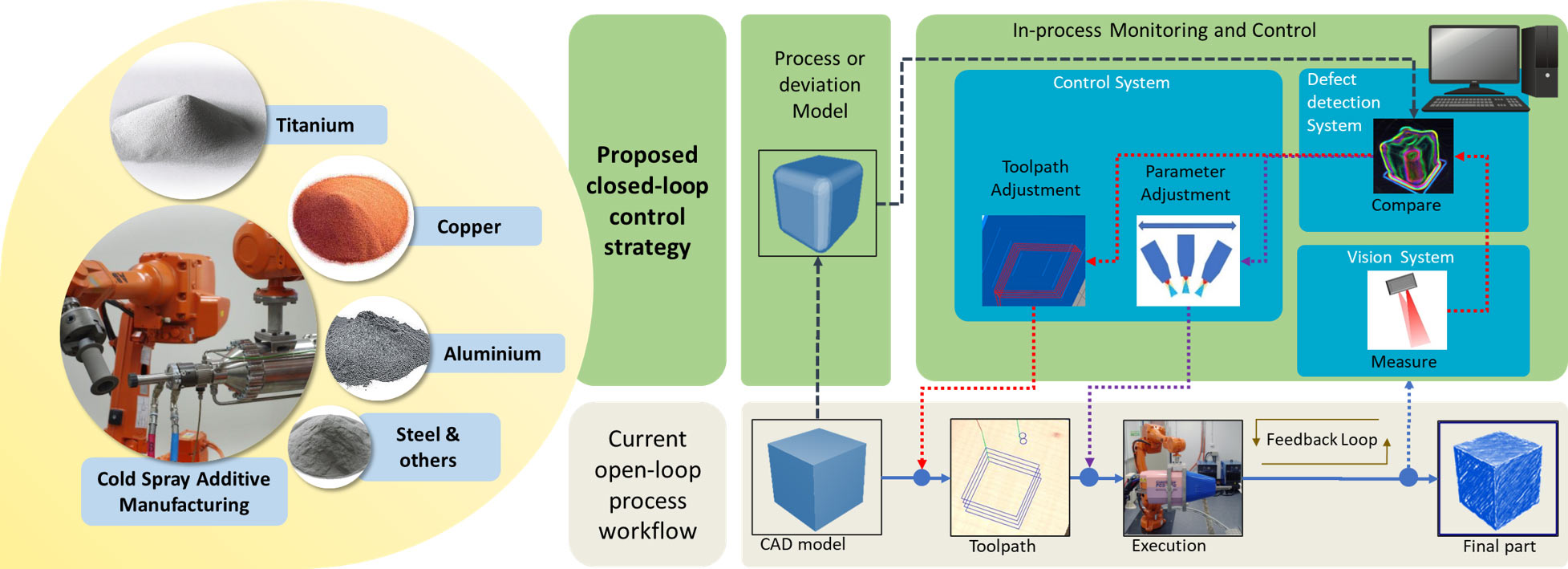

Cold spray technology offers many possibilities for manufacturing complex and freeform metallic parts with a high deposition rate, and it stands out as a potential candidate in rapid manufacturing. However, the current process lacks control over the geometrical shape, which tends to present defects that can be amplificated/propagated during the process. This fundamental problem necessitates a control system with real-time monitoring for consistent geometrical accuracy. So, the research will focus on detecting, measuring, validating, and representing the defects in real-time. Furthermore, the research will explore how to use the information to implement a control strategy by optimising parameters and toolpath planning to amend those defects and obtain the desired shape

This project is conducted in conjunction with CSIRO.

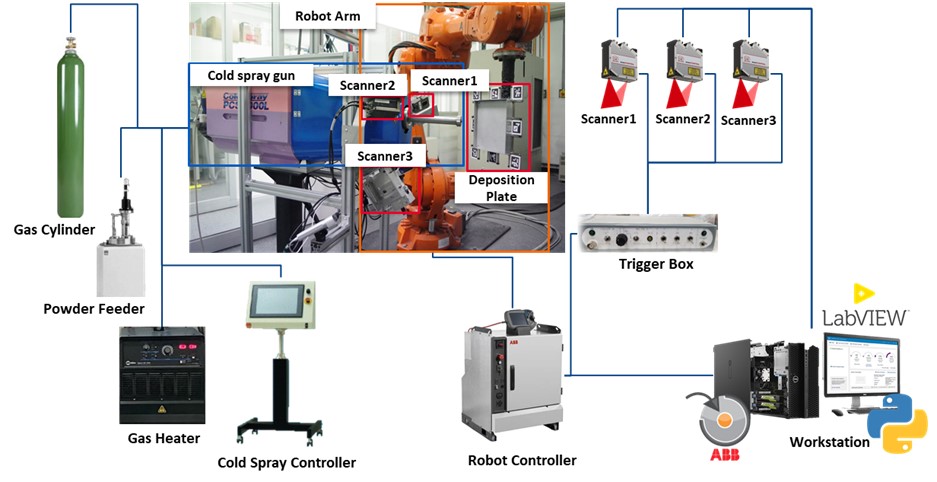

Figure 2: Hardware setup for in-process scanning during CSAM

Figure 2: Hardware setup for in-process scanning during CSAM

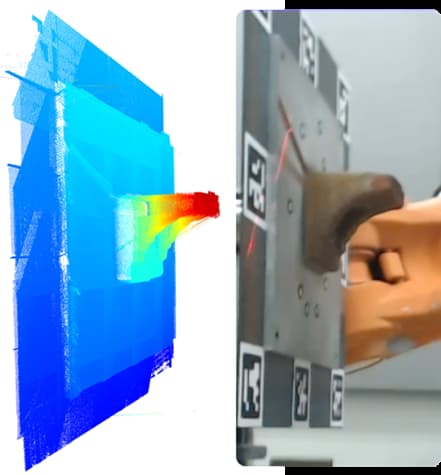

Figure 3: Example of offline point cloud acquisition of a prebuilt object

Figure 3: Example of offline point cloud acquisition of a prebuilt object

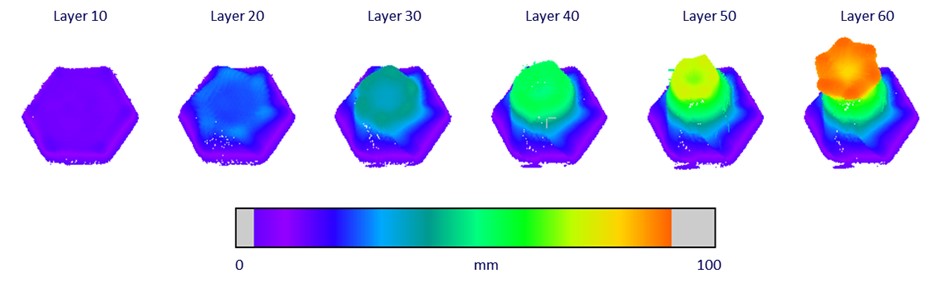

Figure 4: Point cloud reconstructions of an object during the CSAM build process (colormap shows height above the build plate)

Figure 4: Point cloud reconstructions of an object during the CSAM build process (colormap shows height above the build plate)

Metal Fabrication

Cold spray, melt pool, friction stir welding, multifunctional coatings for biomedical Mg alloys, visual monitoring of metal powder