S T Tanushi De Silva

Current powder bed fusion (PBF) systems rely on spherical powders that are known to have excellent flowability & spreadability. These result in the formation of uniform powder bed layers, which is a crucial step to form parts with excellent mechanical properties, e.g. high strength. However, the production of spherical powders relies on expensive production processes such as gas atomisation (GA), plasma rotating electrode (PREP), and plasma spheroidization. The cost of producing additively manufactured (AM) parts can therefore be greatly reduced if more economical (non-spherical) powder feedstocks can be employed.

A key consequence of powder shape is powder flowability, which is traditionally measured via methods such as the Hall flowmeter & Carney flowmeter. However, these methods are run externally to, e.g. PBF systems, and thus only give an indication of how well powders will flow & spread in such end-use applications, particularly fine & irregularly shaped powders. This issue has led to the development of the universal powder bed (UPB) by CSIRO, which can more accurately characterise powder flow & deposition by simulating the powder raking process inside a PBF system.

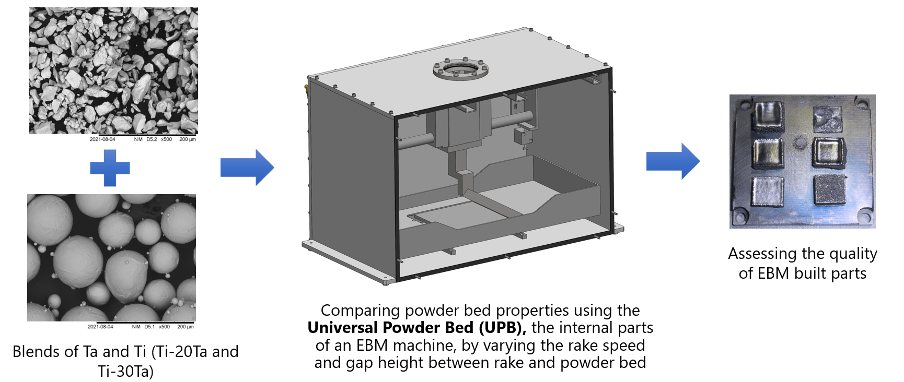

The objective of this research is to economically produce parts with predictable properties from irregularly shaped powders. This will be achieved in two stages; (i) comparing powder bed properties such as percentage of powders within a region, surface roughness, and segregation of spherical & irregularly shaped powders in a UPB system, and (ii) assessing the quality of parts built in an EBAM printer using a blend of spherical & irregularly shaped powders. The irregularly shaped powder used here consists of tantalum, which has potential application as a medical-grade material when alloyed with titanium. This research aims to understand the effects of using irregularly shaped metal powders on both powder bed properties & final part properties. The powder & powder bed characteristics of two titanium-tantalum alloys with 20 wt% & 30 wt% of irregularly shaped tantalum (Ti-20Ta and Ti-30Ta, respectively) will be compared with spherical gas-atomised titanium (GA Ti). Furthermore, test specimens will be built using the powders, and the microstructure, defects, and hardness of these parts will be determined and contrasted in detail.

This project is carried out in conjunction with CSIRO.

Figure 1: Universal Powder Bed (UPB) system developed at CSIRO (Clayton, Australia), which is comprised of the internals of an electron beam melting (EBM) machine. This setup will be used to analyse the behaviour of powders during the powder spreading process.

Figure 1: Universal Powder Bed (UPB) system developed at CSIRO (Clayton, Australia), which is comprised of the internals of an electron beam melting (EBM) machine. This setup will be used to analyse the behaviour of powders during the powder spreading process.

Metal Fabrication

Cold spray, melt pool, friction stir welding, multifunctional coatings for biomedical Mg alloys, visual monitoring of metal powder