ALUMNUS – Current LinkedIn profile including contact details.

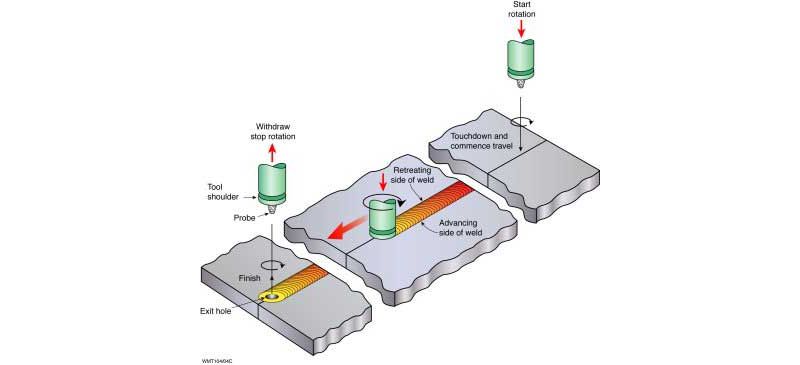

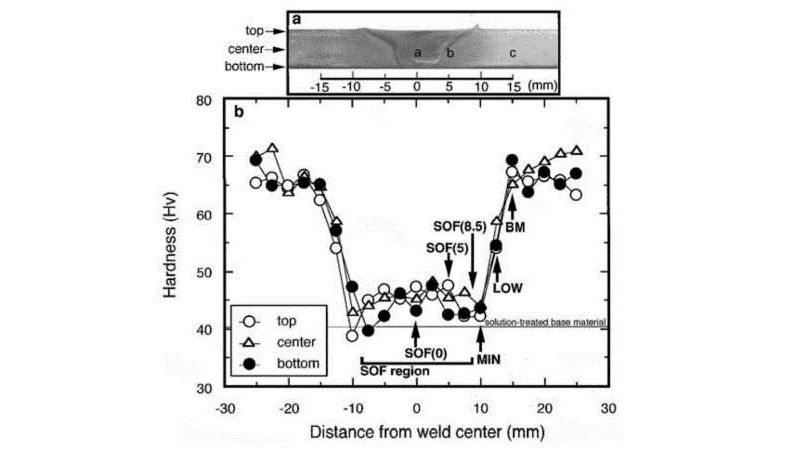

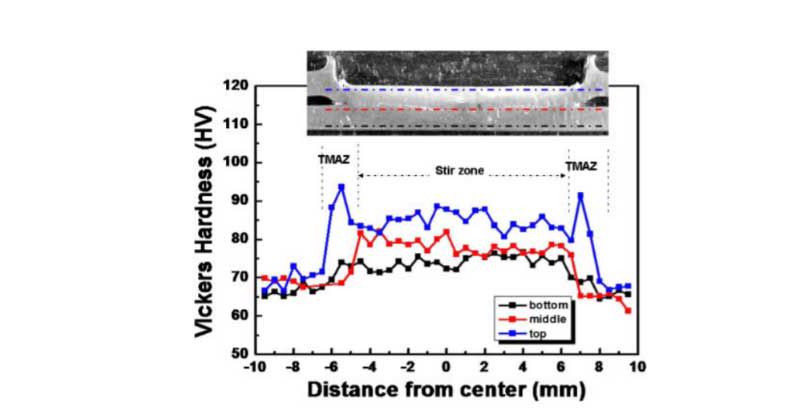

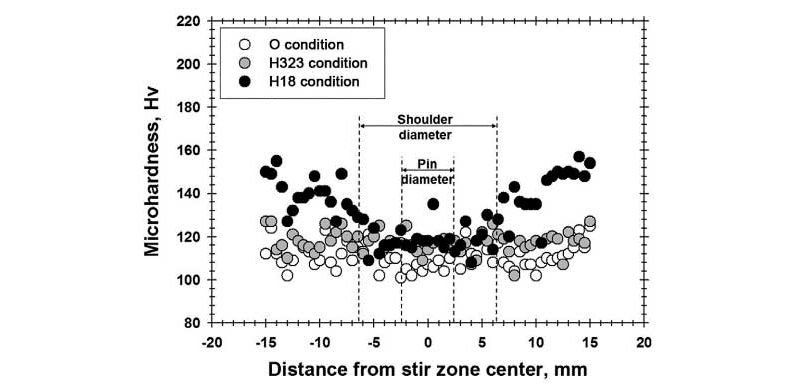

Friction stir welding (FSW) is a solid-state welding process that utilises a rotating tool with a pin & shoulder design to create a sound (defect-free) weld by plastic deforming & mixing of the abutting surfaces (Figure 1). Limitations exist when applying FSW to aluminium and its alloys due to thermal cycle activity & shearing resulting in recrystallisation, grain growth, recovery, and precipitate dissolution. These lead to adverse effects on mechanical properties in & around the weld that can be seen in a plot of hardness vs. distance from weld centre (Figure 2a‑b). Addition of grain refinement, recrystallisation retardant, and thermodynamically stable micro-alloying elements, such as scandium & zirconium, has been shown to increase hardness & improve joint efficiency but these also alter the microstructure. Their effects are also limited for materials in the annealed state, and thus hardened aluminium alloys still suffer a loss of mechanical property upon FSW (Figure 2c). This study will investigate alternative micro-alloying elements for improved mechanical properties of post-friction stir welded aluminium alloys. Other means of weld improvements include optimizing of welding parameters to control heat generation and coupling this approach with micro-alloy optimisation. Cold-working of aluminium and its alloys has shown to increase microhardness by increase dislocation density within the subgrain structure. Micro-alloying coupled with FSW optimization is thus the focus of this research.

Figure 2: Microhardness profile for (a) A.A. 6063-T5 (Sato et al., 1999), (b) A.A. 5025-O (Sun et al., 2011); (c) Al-Mg-Sc-Zr (Malopheyev et al., 2014)

References

S Malopheyev, V Kulitskiy, S Mironov, D Zhemchuzhnikova, and R Kaibyshev (2014). ‘Friction-stir welding of an Al-Mg-Sc-Zr alloy in as-fabricated and work-hardened conditions’, Materials Science and Engineering A, 600, pp. 159-170. DOI: 10.1016/j.msea.2014.02.018.

PMGP Moreira, MAV Figueiredo, and PMST Castro (2007). ‘Fatigue behaviour of FSW and MIG weldments for two aluminium alloys’, Theoretical and Applied Fracture Mechanics, 48, pp. 169–177, DOI: 10.1016/j.tafmec.2007.06.001.

YS Sato, H Kokawa, M Enomoto, and S Jogan (1999). ‘Microstructural evolution of 6063 aluminum during friction-stir welding’, Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 30A(9), pp. 2429-2437. DOI: 10.1007/s11661-999-0251-1.

YF Sun, H Fujii, N Tataki, and Y Okitsu (2011). ‘Novel spot friction stir welding of 6061 and 5052 Al alloys Novel spot friction stir welding of 6061 and 5052 Al alloys’, Science and Technology of Welding and Joining, 16(7), pp. 605-612. DOI: 10.1179/1362171811Y.0000000043.

NJ Teh, H Goddin, and A Whitaker (2011). ‘Developments in micro applications of friction stir welding’. Available at https://www.twi-global.com/technical-knowledge/published-papers/developments-in-micro-applications-of-friction-stir-welding/ (Accessed: 5 June 2018).

Metal Fabrication

Cold spray, melt pool, friction stir welding, multifunctional coatings for biomedical Mg alloys, visual monitoring of metal powder