Ikram Ul Hassan

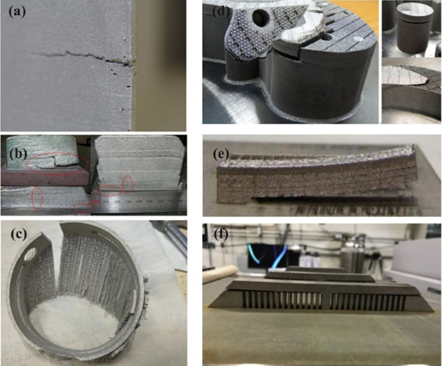

Laser-powder-based directed energy deposition LP-DED is a promising process that uses a concentrated laser beam with high energy density to locally melt material directly into a meltpool, hence reducing the total thermal energy input as compared to other energy sources [1]. It is a highly dynamic, or non-equilibrium, processing technique that involves complex heating & cooling cycles as the laser repeatedly irradiates the material or the material above it [2]. The repetition of these multi-physics processes, e.g. heat flow via different mechanisms, varying solidification rate, irregular columnar-to-equiaxed (CTE) grain transition, solid-state phase transitions, etc., causes various defects in the manufactured part [3]. Although LP-DED has the advantages of higher deposition rate and part density, the parts produced have sub-optimal surface characteristics & other bulk properties [4]. A key example is excessive residual stresses, which initiate cracks that may lead to permanent failure of the part [5]. Part quality defects – either process- or material-induced for LP-DED-fabricated parts, include higher volumetric energy density causing warpage owing to a deeper meltpool, differential thermal material shrinkage, and inter-layer separation due to higher residual stresses; see Figure 1 [2]. Hence, mitigation of residual stresses is a critical area for further research.

Figure 1: (a) Cracks, (b) material shrinkage, and (c) delamination caused by residual stresses [2]

Figure 1: (a) Cracks, (b) material shrinkage, and (c) delamination caused by residual stresses [2]

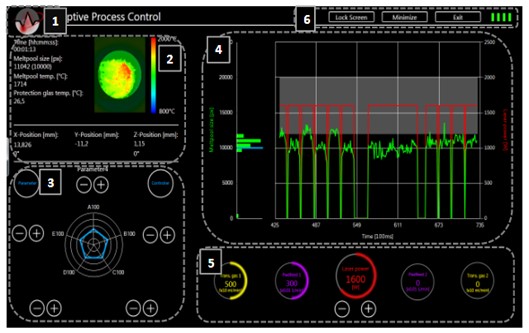

To control dimensional anomalies and enhance quality control, the Lasertec 65 (a hybrid five-axis LP-DED printer from DMG Mori, Tokyo, Japan) incorporates both additive & subtractive operations and presents some process control solutions via its AM Analyzer software; see Figure 2. Its graphical user interface (GUI) allows for data visualisation integrated with a closed-loop monitoring system and thermal cameras that obtain the temperature distribution

history of the meltpool. Reconstruction of 3D models of time-lapsed sensor data are also possible, which enable the location of process anomalies [6]. This thermal monitoring system will assist in evaluating the effectivity of our proposed strategies for residual stress mitigation. The aim of this work initially considers adopting three techniques using the Lasertec 65 to control large thermal gradients, specifically optimisation of scanning strategies, laser remelting for improving surface finish, and mitigation of tensile residual stresses using laser focusing & defocusing. A particular material for study is Inconel 718, for which the effect of phase changes on tensile stresses will also be considered.

Figure 2: (a) Lasertec 65 equipped with (b)

Figure 2: (a) Lasertec 65 equipped with (b)

Figure 2: (b) AM Analyser software providing process information, closed-loop process monitoring settings, and graphical process visualisation in GUI regions 1-5 [6]

Figure 2: (b) AM Analyser software providing process information, closed-loop process monitoring settings, and graphical process visualisation in GUI regions 1-5 [6]

This project is conducted in conjunction with the Surface Engineering for Advanced Materials ARC Industrial Transformation Training Centre (SEAM ITTC).

References

- M Liu, A Kumar, S Bukkapatnam, M Kuttolamadom (2021). ‘A review of the anomalies in Directed Energy Deposition (DED) processes & potential solutions – Part quality & defects’, Procedia Manufacturing, 53, 507-518, DOI: 10.1016/j.promfg.2021.06.093.

- N Ahmed (2019). ‘Direct metal fabrication in rapid prototyping: A review’, Journal of Manufacturing Processes, 42, 167-191, DOI:10.1016/j.jmapro.2019.05.001.

- K Wei, M Lv, X Zeng, Z Xiao, G Huang, M Liu, J Deng (2019). ‘Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed Ti-5Al-2.5Sn alloy’, Materials Characterization,150, 67-77 DOI: 10.1016/j.matchar.2019.02.010.

- A Dass, A Moridi (2019). ‘State of the art in Directed Energy Deposition: from additive manufacturing to materials design’, Coatings, 9, 418 DOI: 10.3390/coatings9070418.

- D Ahn (2021). ‘Directed Energy Deposition (DED) process: state of the art’, International Journal of Precision Engineering and Manufacturing-Green Technology, 8, 703-742, DOI: 10.1007/s40684-020-00302-7.

- DMG MORI Australia (2022). ‘Lasertec 65 DED hybrid - Additive manufacturing machines by DMG MORI, DMG MORI Australia - CNC machine tools for all cutting-machining applications’, https://au.dmgmori.com/products/machines/additive-manufacturing/powder-nozzle/lasertec-65-ded-hybrid, accessed 12th October 2022.

Metal Fabrication

Cold spray, melt pool, friction stir welding, multifunctional coatings for biomedical Mg alloys, visual monitoring of metal powder