New wastewater tech tackles fatbergs at the source

A new wastewater treatment system developed by RMIT University researchers could help prevent fatbergs – solid masses of fat, oil and grease (FOG) that clog sewers and cost water utilities globally billions to remove each year.

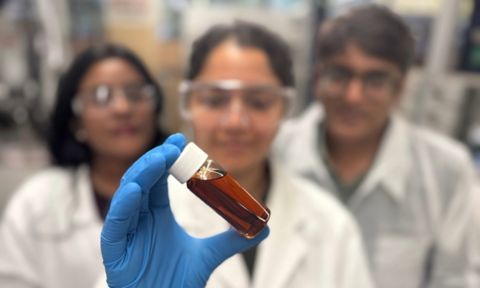

Aussie tech helps make bio-oils for greener industrial applications

Australian technology developed at RMIT University could enable more sustainable and cheaper production of bio-oils to replace petroleum-based products in electronic, construction and automotive applications.

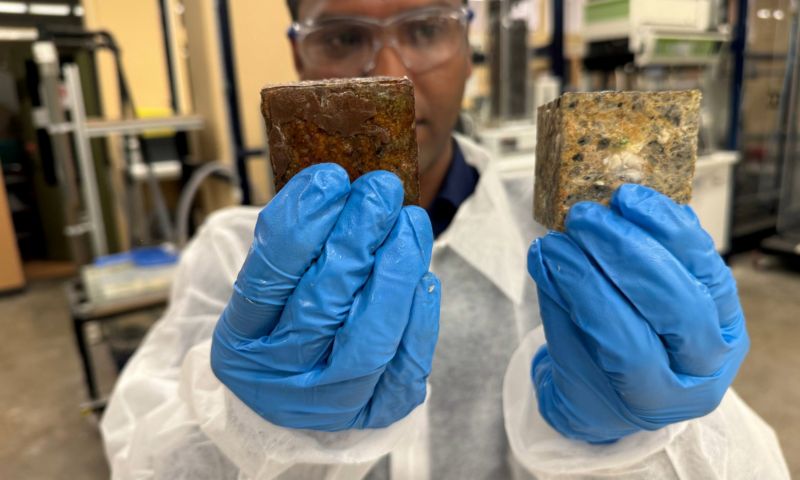

Anti-fatberg invention could help unclog city sewers

Engineers from RMIT University have invented a protective coating for concrete pipes that could help drastically reduce the formation of fatbergs in sewers.

Time to count plastics in climate action and counter Trump effect

Scientists from RMIT University are calling for countries to include carbon emissions from plastic production and waste in their climate action plans before the upcoming United Nations Climate Change Conference of the Parties (COP 30) in Brazil.

World-first green hydrogen innovation wins prestigious Climate Innovation Challenge

South East Water and RMIT University's ground-breaking method for producing green hydrogen from solar energy and recycled water has won the 2024 Water Minister’s Climate Innovation Challenge.

Magnetic material mops up microplastics in water

Researchers at RMIT University have found an innovative way to rapidly remove hazardous microplastics from water using magnets.

.jpg)